Ten Engine Terms you Need to Know

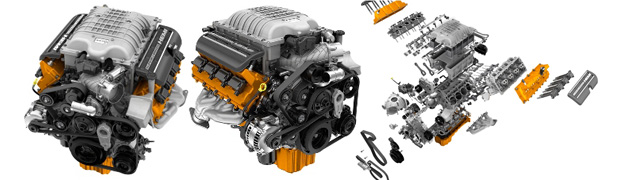

When it comes to making horsepower, engine builders will talk about all kinds of words, terms, and ideas that will probably go over your head if you’ve never torn down your engine block. However, JK-Forum is here to help you out by giving you ten terms to help you understand some of those ideas your builder is talking about. However, there are more than just these ten and we’ll continue to visit more later.

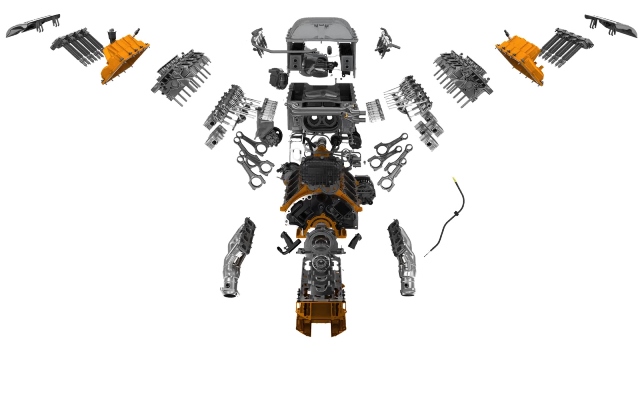

Rod to Stroke Ratio – The Rod to Stroke Ratio is the ratio of the length of the connecting rod to the stroke of the crank. You get this by dividing the rod length from the center of the “big end” where the rod connects to the crankshaft and the “small end” where the piston pin goes through. You can do it in inches, but most find millimeters a little easier to deal with. The lower the ratio, the higher the angle of the rod, which pushes the piston into the cylinder walls harder, thus creating more wear and friction. A higher ratio means a lower rod angle, but air will not fill the intake ports with the same velocity, and there is less demand for better port flow. In other words, there is very weak torque at lower revolutions. Most builders will try to stay between 1.5:1 and 1.8:1. MotoGP and Formula 1 cars usually have a ratio of 2:1.

Rod to Stroke Ratio – The Rod to Stroke Ratio is the ratio of the length of the connecting rod to the stroke of the crank. You get this by dividing the rod length from the center of the “big end” where the rod connects to the crankshaft and the “small end” where the piston pin goes through. You can do it in inches, but most find millimeters a little easier to deal with. The lower the ratio, the higher the angle of the rod, which pushes the piston into the cylinder walls harder, thus creating more wear and friction. A higher ratio means a lower rod angle, but air will not fill the intake ports with the same velocity, and there is less demand for better port flow. In other words, there is very weak torque at lower revolutions. Most builders will try to stay between 1.5:1 and 1.8:1. MotoGP and Formula 1 cars usually have a ratio of 2:1.

Compression Ratio – This is the ratio in relation to the capacity of the cylinder from its largest capacity (bottom dead center) to its smallest (top dead center). A higher compression ratio can increase torque and power; however, it comes at the risk of detonation and engine ping, thanks to higher heat inside the cylinder, so you’ll have to run higher octane fuels to make up for it. A lower compression ratio can mean lower power and torque, but you don’t have to run as high an octane thanks to lower cylinder temperatures. Factors that make up compression ratio are piston design, rod length, crank stroke length, combustion chamber volume, and head gasket thickness.

Stroker Crank Shaft – A stroker crank shaft is simply a crankshaft that has a longer stroke over what originally came in the engine. This is done by modifying the original crankshaft journals by offsetting them by welding and re-grinding or having a new crankshaft made. Offsetting journals by welding and grinding them does increase the risk of making the crankshaft more brittle as you heat the metal from welding and grinding.

Dished Piston – A dished piston is exactly as it sounds: a piston with a dished-out combustion area. You’ll see this in applications that need a lower compression ratio, such as turbocharged engines.

Domed Piston – A domed piston is exactly as it sounds, too: a piston with a domed-out combustion chamber. This will increase the compression ratio, and it isn’t always a true, round dome. It is shaped to fit the combustion chamber, and it also features cutouts for the valves to prevent, or try to prevent piston-to-valve contact.

Direct Fuel Injection – A fairly modern invention for gasoline engines, but this technology has been around for diesels since the 1930s. The injector, much like a spark plug, has its nozzle inside of the combustion chamber rather than in the intake ram or at the throttle body. This has allowed for more precise injection timing, the amount of fuel that is needed to be injected into the cylinder, and improved cylinder temperatures. Injection timing can now wait until the precise moment for maximum combustion rather than wait on the valve to open.

Direct Fuel Injection – A fairly modern invention for gasoline engines, but this technology has been around for diesels since the 1930s. The injector, much like a spark plug, has its nozzle inside of the combustion chamber rather than in the intake ram or at the throttle body. This has allowed for more precise injection timing, the amount of fuel that is needed to be injected into the cylinder, and improved cylinder temperatures. Injection timing can now wait until the precise moment for maximum combustion rather than wait on the valve to open.

Variable Valve Timing – Variable valve timing is a camshaft timing control that changes when the valve opening occurs and how long or short the valve stays open. This can be done by a hydraulic phaser that uses engine oil and will move the camshaft within a certain degree of the cam timing gear. We see this in the Pentastar V6 for the Cherokee, Grand Cherokee, and Wrangler.

Equal-Length Header – An equal-length header is designed to time the exhaust pulses to help with exhaust scavenging. Each exhaust pulse will help pull the next when they merge at the header collector thanks to a low-pressure zone behind each exhaust pulse.

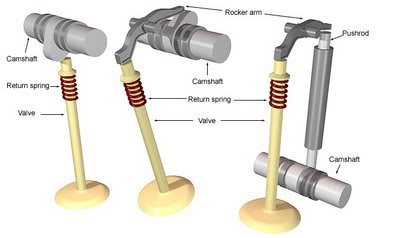

Shim Over Bucket Valve versus Rocker Arm – There are two types of valve actuation that you’ll see on modern engines. The first is a Rocker Arm style and is done by either a direct connection of the rocker to the camshaft, or by a pushrod and follower acting on the rocker arm at the camshaft. The second is the shim over bucket design that allows the camshaft to act directly onto the valve. There is a “bucket” that sits over the valve spring and a shim fits in between the bucket and camshaft for proper clearance.

Shim Over Bucket Valve versus Rocker Arm – There are two types of valve actuation that you’ll see on modern engines. The first is a Rocker Arm style and is done by either a direct connection of the rocker to the camshaft, or by a pushrod and follower acting on the rocker arm at the camshaft. The second is the shim over bucket design that allows the camshaft to act directly onto the valve. There is a “bucket” that sits over the valve spring and a shim fits in between the bucket and camshaft for proper clearance.

Camshaft – The camshaft is the mechanical means of operating the valves. There can be a single cam that is located in the block, which is known as the overhead valve (OHV) that uses a follower and pushrod to actuate the rocker and valve. The other is the overhead cam (OHC). This can be a single over-head camshaft that operates both the exhaust and intake valves, or a dual overhead camshaft that has a camshaft for intake valve operation and a camshaft for exhaust valve operation. The camshaft has lobes on it that control the duration (the time the valve is open, which is measured in degrees) and lift (the amount the valve opens, which is measured in length of inches or millimeters). The duration of the exhaust and intake valves can also determine the amount of overlap there is to help with cylinder evacuation and filling.