Custom modular JK hardtop

#321

JK Super Freak

Thread Starter

The recent Jeep Africa concept has gotten me thinking seriously about a design for side-mount Jerry can/Rotopax carriers for the JK... since it's a bit off-topic for this thread I've started a new thread on the idea: https://www.jk-forum.com/forums/jk-s...5/#post4088537

Please check out the thread and give me any feedback you might have on the idea.

Please check out the thread and give me any feedback you might have on the idea.

#323

JK Enthusiast

Join Date: Mar 2012

Location: Orlando, FL

Posts: 216

Likes: 0

Received 0 Likes

on

0 Posts

I need that first picture for my JK....

As part of my fiberglass work for the past few days, I molded a pair of rear door jambs for the soft side version of the Safari Cab. You've seen the parts in this next photo already - the hard side panels bolted to the rear panel with the drip rail clamped on top for now; the drip rail will be part of the roof panel assembly when everything goes together. Removing the hard side panel, one of the soft side jambs has been put in it's place: The jambs provide a place for the back of the doors to seal (either the back of the rear doors for the JKU or the back of the front doors for the JK 2dr), and they also provide a place for the soft sides to attach. A few more views of the jambs in place: Yesterday and today I molded a few other parts as well, photos of them soon.

#324

JK Super Freak

Thread Starter

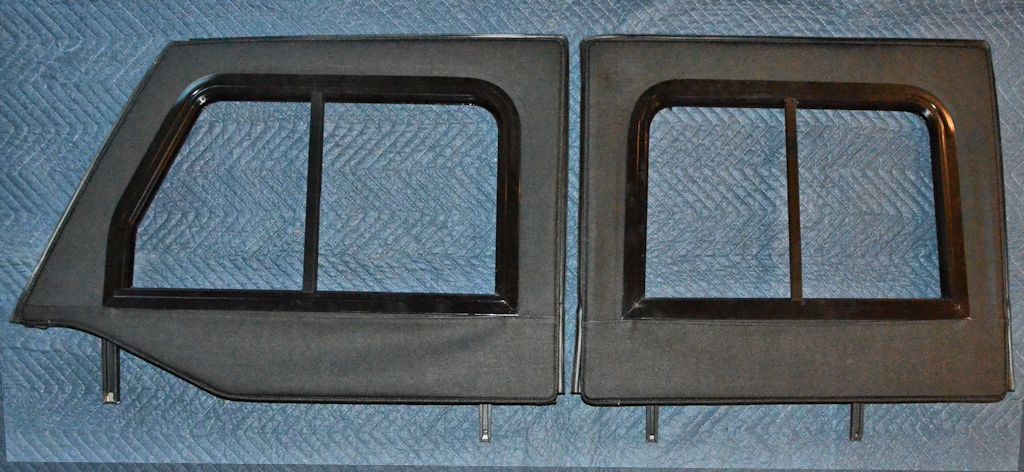

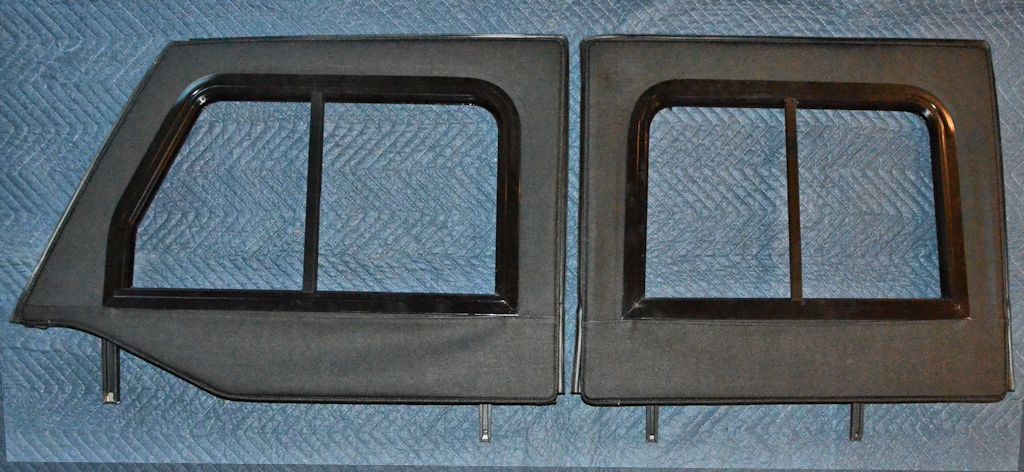

Yesterday I met with the window company that I've been working with on the JK half door slider project. Here's a peek at the windows, these are just the frames with no glass. In this photo the windows are mounted in factory uppers - I've sized the windows so they can also be used to upgrade the factory uppers from zippered vinyl windows to glass sliders. There are only a few more details to take care of before the windows are ready for production.

Another topic of the meeting was fitting sliders in the JK hardtop. I while back I made up a test frame with curved surfaces to match the curves of the hardtop, and I made up a proof-of-concept retrofit kit to allow standard flat RV windows to install in those curved surfaces (photo of the test fixture are below). I brought the test fixture to the meeting and reviewed the idea with them. They had some additional suggestions, and gave me some materials to test with, so I'll implement their suggestions with my test window and fixture.

For the record: I'm not an employee of the company that will be marketing the slider windows. I'm just doing the design project because it's fun for me to do.

Another topic of the meeting was fitting sliders in the JK hardtop. I while back I made up a test frame with curved surfaces to match the curves of the hardtop, and I made up a proof-of-concept retrofit kit to allow standard flat RV windows to install in those curved surfaces (photo of the test fixture are below). I brought the test fixture to the meeting and reviewed the idea with them. They had some additional suggestions, and gave me some materials to test with, so I'll implement their suggestions with my test window and fixture.

For the record: I'm not an employee of the company that will be marketing the slider windows. I'm just doing the design project because it's fun for me to do.

#326

JK Super Freak

Thread Starter

The way I've drawn the concept, I'd use the fiberglass upper door jambs; they'd provide a very weatherproof surface for the doors to seal against, and provide a good place to secure and seal the soft panel.

#328

JK Super Freak

Thread Starter

Project update - I haven't made much progress on the JK Safari Cab for the past month or so because several other of my design projects have recently been picked up by two different companies to become commercial products, and that's been keeping me pretty busy. I hope to be getting back to the Safari Cab project shortly. Next up is making the mold master and then the mold for the main roof panel. Once that's done I'll mold a roof and begin assembling the parts on the JK.

One of the side projects that came out of JK Safari Cab work is a retrofit kit for installing opening windows in the JK hardtop. I've been playing with a bunch of different style opening windows for the Safari Cab (sliders, tilt-ups, etc.), and they're really easy to install in the Safari Cab because I made the window mounting surface flat. But installing the same windows in a factory hardtop is presents a few challenges because the JK hardtop window mounting surface is curved and standard RV-style windows require a flat mounting surface.

I have been working on this with an RV window company, and I now have what I believe will be a cost-effective solution to the curved surface problem. I've been doing my testing in a curved test fixture I made a few months back to simulate the curved mounting surface of the factory hardtop, and I've resolved the mounting and sealing issues that the curved surface causes. I don't know if there would be enough interest to make the retrofit worth doing, but at least now the main technical issues are resolved.

One of the side projects that came out of JK Safari Cab work is a retrofit kit for installing opening windows in the JK hardtop. I've been playing with a bunch of different style opening windows for the Safari Cab (sliders, tilt-ups, etc.), and they're really easy to install in the Safari Cab because I made the window mounting surface flat. But installing the same windows in a factory hardtop is presents a few challenges because the JK hardtop window mounting surface is curved and standard RV-style windows require a flat mounting surface.

I have been working on this with an RV window company, and I now have what I believe will be a cost-effective solution to the curved surface problem. I've been doing my testing in a curved test fixture I made a few months back to simulate the curved mounting surface of the factory hardtop, and I've resolved the mounting and sealing issues that the curved surface causes. I don't know if there would be enough interest to make the retrofit worth doing, but at least now the main technical issues are resolved.

#330

JK Super Freak

Thread Starter

Getting the windows manufactured is the easy part. The RV window company I've been working with on the half door upper sliders is very flexible about quantities, they'd do a minimum order of 5 pairs of windows at a very attractive price, and there's no up-front investment in tooling required (in most cases), so windows could be manufactured with very little up front investment. There is the question of which style to make (slider, swing-up, combo swing-up/slider, etc.), and which sizes to make them - there are 4 different sizes - the early years have smaller windows than the later years, and of course the 2 door windows are a different size than the 4dr, so there are 4 different sizes. All of that isn't a big deal, that could be figured out.

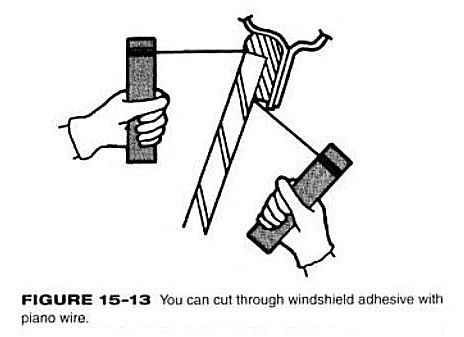

I think the level of interest people might have will be determined by what's involved in the installation procedure. The factory windows are bonded (glued) in place, so removing them takes some work. At the DIY level usually it involves sticking a piano-wire type tool through the adhesive at one point, and pulling it around the perimeter of the window, one end of the wire outside the hardtop and the other end inside. It usually isn't easy. Here's an illustration from and Auto Body textbook:

Then it's likely the window opening will need to be trimmed larger. That's not too hard on a fiberglass hardtop, but here's why it would probably have to be done. This first photo shows the window mounting surface, it's pretty wide because of the bonded window:

If an RV-style window were sized to fit in that opening, it would be something like this:

I doubt people would be happy with that size window, plus the area of the window mounting surface outside of the window frame would probably have to be touched up - removing the factory window adhesive probably wouldn't leave that area looking presentable.

If the window opening were trimmed larger, a larger window would look something like this:

The hardtop is a variant of fiberglass, so it can be trimmed with a jigsaw and the correct type of blade.

So the first question is how many people would want to tackle this as a DIY job? Or would an installation service have to be offered?