GenRight Off Road: JK-Forum Takes a Closer Look

Tony Pellegrino’s shop elevates the entire off-road market by challenging the status quo.

There are Jeep shops, and then there are Jeep Engineering Shops. While you see more and more of the former popping up with cheap LED lights and lift kits that don’t give you any travel, the latter maintains staying power. GenRight Off Road sets a hard-to-match precedent. Lack of innovation and quality drove Tony Pellegrino to start the company. Today, we’ll detail both his and the company’s humble beginnings as well as what he feels is the problem with the state of off-roading and Jeeps.

What does GenRight stand for? “It was actually my original partner who chose that name, and it’s short for ‘Genuine Ideas Engineered Right.’ It was the only thing he wanted to contribute other than the funding of the company.”

That partner just wanted to be the investor who helped get GenRight off the ground. But why did Tony start the company? Well, the story has a rather interesting twist on the old adage, “Necessity is the mother of invention.”

Tony was always into off-roading. From racing dirt bikes — including winning a trophy handed to him by AMA Hall of Famer Roger DeCoster — to crawling in Jeeps, if it touched dirt he was interested. In 1999, he built the truck that would eventually start the company: the Growler YJ.

“It all started with it, and at the time it was still black,” Tony said pointing to an article on the YJ. “At the time I wanted to install ProRock 60s, and when you do that, you have to move the axle back to set it up close to the original axle’s location.”

Because its pumpkin is bigger, you can’t install it in the original axle’s position. If there, it would contact the Jeep’s rear-mounted gas tank. “So I called down to the manufacturer, asked about how I can do it, and they said, ‘Well, we’ve never run into that issue.’ So, now I’m thinking, ‘Well, I guess I’m fixing it myself, then.’”

‘In [my first-ever show], I sold 50 gas tanks. I knew right away it was going to be hot within the first couple of months of business.’

Tony saw himself as a manufacturer even before starting GenRight, as evidenced in a picture of an RC truck in his office. He built the truck, which features many parts we now take for granted thanks to companies like Axial. However, you would have most likely seen it in the XO Bar System, a bolt-on external roll cage from before GenRight became a company.

GenRight’s first product was their aluminum Crawler Extreme fuel tank designed to fit with larger axles on the Jeep YJ. Tony wasn’t sure if something like that had any demand until everyone he showed asked him where he got the gas tank. That impression expanded when he showed he could extend the wheelbase even farther by moving the axle seven inches back to fit larger tires while keeping the 100-inch wheelbase.

No one else was addressing what was a far more common problem than even he realized. Tony did all this in his garage. He marketed it by taking the Growler on the road to Terra Del Sol, to Moab, to Johnson Valley — anywhere Jeepers went — to help show it off. At the company’s start, he shipped everything himself, too.

“If I had built another bumper or another rocker,” he admits when asked about how GenRight became successful at its start, “I would have just been another company in that saturated market.” His first-ever show as GenRight came at Terra Del Sol. “In that two-day event, I sold 50 gas tanks. I knew right away it was going to be hot within the first couple of months of business.”

‘My preference is to be over at the R&D building

getting my hands dirty and making parts.’

From his garage, the business grew to what it is today with one building for the race shop and R&D, and the other for manufacturing and shipping. However, he’s stayed within Simi Valley, California, his home in the Golden State. “It’s turned into a really nice company, and I still really enjoy it.” However, Tony doesn’t do much of the designing and R&D that he used to, “My job now is more of a desk job, but my preference is to be over at the R&D building getting my hands dirty and making parts.”

Even with as many parts as GenRight has on the market today, there are 77 more on the drawing board. However, the term “drawing board” isn’t the same as when he started the company.

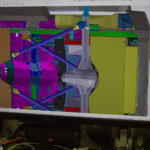

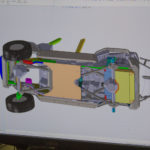

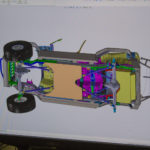

The parts made by GenRight are not just manufactured there. They’re also designed first on Richard Hunt’s computer using Solidworks. Not only does this make testing that much faster thanks to the level of detail you can put into the program, but it also helps with the actual manufacturing, too.

“What’s really neat is that we can design each cut in Solidworks,” says Richard, “From our race trucks to the cages we offer, each cut is designed in the program and then laser cut after bending. It has the angle made so our fabricators can lay the right bead down and it neatly comes together like a Lego set.”

While you may think that’s only for ease of their manufacturing, the DIY cage kits that you weld together are also designed exactly in this same way. Save for the tools, you get everything you need for everything they sell in the correct package. Both the ease of putting the parts together and having every part you need is another core philosophy that encouraged Tony to start the company.

“Like everybody,” Tony said, going back to the Growler, “I went to club meetings and went on the forums and everyone would tell you to buy axles from one guy, arms from another, and steering parts from that other guy. You get everything on the floor and start asking yourself, ‘Whose idea was this? None of this stuff really goes together.’ Even then, you’re still missing half the stuff, and that’s when I asked myself, ‘If this is really the best the market has to offer, it’s bad.’”

It is rather inconvenient when you must run to the parts store (that’s probably closed because you’re either wrenching on the weekend or at night after work) trying to find that oddball bolt or nut that only exists in a McMaster-Carr catalog. Wasted time and frustration lead to a bad first experience if you’re just starting out.

While going to shows helped launch the company, the racing helped sell a lot of enthusiasts on GenRight products. Specifically, that applied to aluminum parts, once thought of as a metal only worth being used for beer cans. At the time (and still somewhat true whenever an aluminum JL is brought up), the typical response to aluminum parts and bumpers was a loud “no way.” “Those steel bumpers were so heavy,” Tony explained, “And, yeah, they are heavy-duty, and you can drive your Jeep by Braille and bang into every rock, but I didn’t want to do that. I wanted to learn how to drive clean, I wanted my Jeeps to look nice, and I started coming out with aluminum stuff.”

Those aluminum parts are still plenty strong, as Tony has shown on all his demonstrator Jeeps. It also took the weight off. Aluminum components on the YJ remove 400 pounds when compared with the aftermarket steel bumpers, fenders, and rockers. Aluminum’s weight reduction with the JK rises to around 600 pounds lighter. “It’s a huge difference, and all of those parts are up high, too,” he pointed out.

“It fixes a lot of the problems that steel parts create. Aluminum parts lower the center of gravity, they reduce the strain on the engine from carrying less weight, they improve gas mileage – [aluminum] fixes a lot of things.” It wasn’t a drastic switch to start making more aluminum parts, too. The gas tanks they made were already aluminum, so all the fabrication and tooling was already in place. GenRight simply switched to bumpers, fenders, rockers and other parts that were typically steel.

Then Tony raced in the King of the Hammers with his aluminum-shod Jeep, and GenRight aluminum parts became an instant hit. “If it wasn’t for GenRight,” he says, “I wouldn’t be racing.” The original reason he raced in the King of the Hammers was to build brand awareness and create credibility in the market for his company. “I wanted people to say, ‘That guy is the owner of GenRight and he’s podiumed KOH.’” Tony said this was at a time when few shop owners were finishing the race, let alone reaching the podium.

Both the racing and the day-to-day of GenRight have become a family affair flanked by 35 employees. Each day they are open, Tony’s son, Jordan is helping weld cages for customer builds and shop cars, Tony’s daughter, Jami is taking photos or helping design parts, and Tony’s wife, Debbie is making sure the company is running smoothly on the financial side.

During Ultra4 events, Jami races in the Polaris RZR XP 1000, Jordan is in the Modified Class Jeep JK, and Tony is in the Unlimited GenRight Nexus. Crewing on all three vehicles is Darren Ruzicka, who has been with the company as a fabricator, and has been working on those race vehicles since the company’s early start nearly 11 years ago. Being around that long, you might as well consider him family now.

GenRight and Tony have both weathered some tough issues in their existence, including the breakdown of the economy eight years ago. Despite that, they are both still here and constantly growing.

What does he see as the problem with the current state of the off-road industry? “You know,” Tony begins, “I’m of the perspective that I don’t mind working on my vehicle, but I don’t want to work on it out on the trail. I’ve […] known guys who had to buy a trailer because their vehicle broke so bad it wouldn’t get back home, and this is after spending a grand on gas alone. So, instead of spending the money on a quality product and enjoying their time with their family, they [were] left fixing their vehicle on the trail.”

Do it right the first time and you won’t have to do it again the second time. That’s a good philosophy to stand on when building anything. However, it’s getting harder to figure out what company is making a legitimate product thanks to the savvy of marketing and social media manipulation.

While not as easy as it was a few years ago, it’s still possible to create social buzz for a company when one hits the right viral campaign. Like those who sell you the same product made overseas, but they do it directly, or those who generate a following with pretty pictures and good-looking boxes because you know if they took the time to make a good-looking box, they had to take even more time to make the product right, right?

We’ll fill you in: no.

“We’ve had guys come up to us and say, ‘I liked this bumper because it had the right style,’ only to find out it’s overweight and built cheap,” Tony said. In 2006, GenRight made the transition to aluminum bumpers. Going back to our earlier mention of aluminum, you’ll understand the point here. It’s a perception issue about accepting things at face value and even accepting old ideals instead of looking deeper. “I’ll point out one thing: You look all over this shop and on our Jeeps, and you won’t find anything with a ball joint installed.”

He’s right, every vehicle in the shop has rod ends installed. “You’ll have guys claim ball joints will last just as long because that’s what they have been using forever and I’ll tell them, ‘No problem. You run whatever you got across the desert at over 130 mph with ball joints installed. I’ll stick with my rod ends and see how long they actually last.’ I’m not putting my life on that.”

However, Tony admits that not all rod ends are created equal, either. That goes back to the shiny package and slick marketing to sell you something that was cast too thin or machined to move like garbage. “Just like anything else, you can buy cheap rod ends. We run with FK Rod Ends which are made from 4340 aluminum. They aren’t cheap, but we know they are good quality [….] Again, it comes back to that bottom line of you get what you pay for.”

When it comes to Tony Pellegrino and GenRight, it’s a full circle. It’s the same message driven this entire time: buy quality, be complete, and do it right the first time. From the innovation of that aluminum gas tank to the aluminum bumpers and fenders, and even to the use of carbon fiber, GenRight and Tony have pushed away common misconceptions of how a Jeep should be built. They demonstrate that it’s quality at the end of the day that counts more.

ALSO SEE: What the Forum Has to Say About GenRight Off Road

The purpose is not about making the heaviest steel parts. GenRight takes care in building products that fit and won’t break if you happen to wing it on a boulder. It’s not about the viral social media page and shiny boxes at cheap prices. It’s about doing it right even if it costs more because your time on the trail is more valuable than a broken Jeep. While, yes, this has been an article that speaks well about Tony and his company, the more important message to take away is to avoid buying cheap, fake parts. The more we accept that cheap is good, the worse our products will become, and the less we’ll all be out in Johnson Valley, Moab, or wherever you happen to go Jeepin’.