All About Turbochargers – Part 5: Blow-Off Valves

Blow-off valves have it easy. They don’t see the heat of their friend the wastegate, but their job in the turbocharger system is just as important. Without them, the excess boost pressure from your letting off your Jeep’s throttle would cause compressor surge, and that gets expensive.

What is compressor surge, and why does it happen? When you let off the gas to slow down, shift, or stop, the throttle plate closes and stops the incoming boost pressure from reaching the intake manifold. While this is happening, the turbocharger is still spinning, creating more boost pressure. With nowhere for that boost pressure to go, the compressor wheel slows down. This adds stress on the bearings and shaft between the compressor and turbine wheels, and could potentially break the compressor wheel, shaft, damage bearings, or all of that at one time. If your turbo can take it, your charge pipes might not, and they could burst. Either way, it will mean no boost for you.

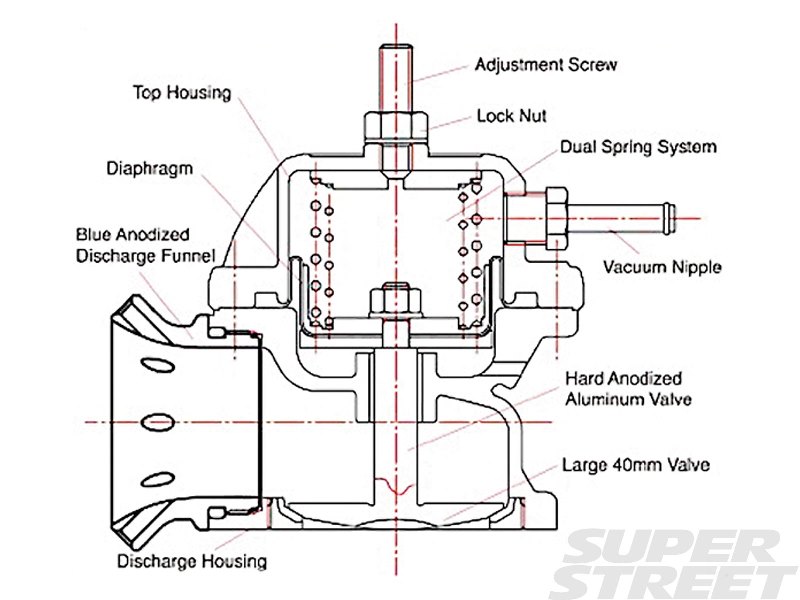

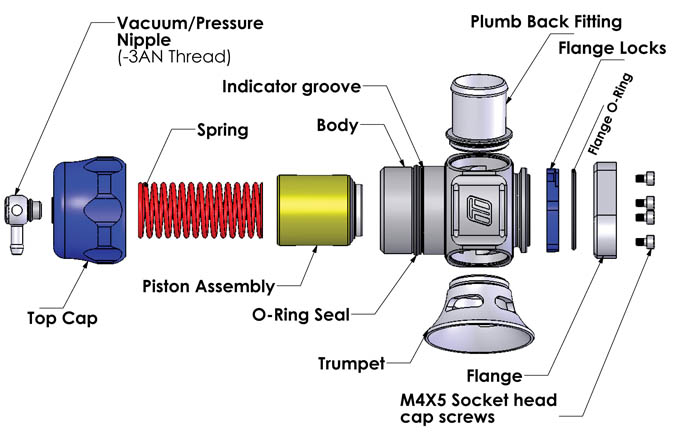

Installing a blow-off valve before the throttle body on the charge piping is a way to bleed pressure in those situations. You’ve got two different ways to vent boost pressure out of the charge piping: either vent it into the atmosphere or recirculate it back into the charge piping.

Atmospheric dump creates that well-known “whoosh” or whistle noise you hear when a turbo car boosts and immediately closes the throttle. This simpler design is best used in speed density tuning because it calculates airflow by engine RPM, throttle position, and a Manifold Absolute Pressure sensor. It’s easier for it to compensate for lost boost pressure because it’s going to be looking for the right calculation based on RPM, throttle maps, and MAP rather than what’s actually coming in. It knows that boost will be coming even though you dumped what was coming in.

Now, those are not hard facts in where each will be used. There are plenty of MAF guys who use an atmosphere dump, and there are speed density guys who use bypass blow-off valves. It’s a matter of tuner preference.

In the next article, we’ll discuss how to keep boost in check, and even modify it using a boost controller.