Measuring LCAs with flex joints and bends?

#21

Super Moderator

Thread Starter

Well, I'm getting ready to adjust these arms now. I got the angle finder, but I'm a little unsure how much it's going to help.

Here's the problem.

I pulled one of the arms off, used the jack in the process to make it easier to slide the bolts off. I loosened the nuts on the other arm but didn't remove it, since my original plan was to adjust the length of one arm and then mount it, pull the other arm, adjust length and then install.

So I measure my current pinion angle with the one arm still attached.....it read 8.3 deg. So that doesn't seem like a useful measurement seeing as though, my caster from the alignment shop was 2.9deg driver side, 2.5deg passenger. My drive way, seems pretty "level". I actually put a level on the cement next to each tire, and it showed to be pretty flat at each level.

Next plan. I adjusted the flex joint, so that the joints are parallel. It now measures 22 1/2in on both sides of the control arm. I'm going to adjust it out so it measure 23in.

Hopefully a 1/2in increase in length makes sense and puts me in the 4-5 deg range of caster when all is said and done. I'll measure the pinion angle after install, but I just don't know how much I can trust that angle measurement given all the unknown variables. I really wish I had measured the pinion angle before pulling that arm off.

Summary

Arm length = 22 1/2in => Caster from alignment shop = 2.5 Deg

Arm length = 23in => Caster= hopefully close to 5 deg

I'm going to get an alignment check afterwards regardless. I just didn't want any surprises where I need to adjust them again.

I knew I should have went with Geo brackets!!! LOL!!

Here's the problem.

I pulled one of the arms off, used the jack in the process to make it easier to slide the bolts off. I loosened the nuts on the other arm but didn't remove it, since my original plan was to adjust the length of one arm and then mount it, pull the other arm, adjust length and then install.

So I measure my current pinion angle with the one arm still attached.....it read 8.3 deg. So that doesn't seem like a useful measurement seeing as though, my caster from the alignment shop was 2.9deg driver side, 2.5deg passenger. My drive way, seems pretty "level". I actually put a level on the cement next to each tire, and it showed to be pretty flat at each level.

Next plan. I adjusted the flex joint, so that the joints are parallel. It now measures 22 1/2in on both sides of the control arm. I'm going to adjust it out so it measure 23in.

Hopefully a 1/2in increase in length makes sense and puts me in the 4-5 deg range of caster when all is said and done. I'll measure the pinion angle after install, but I just don't know how much I can trust that angle measurement given all the unknown variables. I really wish I had measured the pinion angle before pulling that arm off.

Summary

Arm length = 22 1/2in => Caster from alignment shop = 2.5 Deg

Arm length = 23in => Caster= hopefully close to 5 deg

I'm going to get an alignment check afterwards regardless. I just didn't want any surprises where I need to adjust them again.

I knew I should have went with Geo brackets!!! LOL!!

Last edited by Rednroll; 08-08-2017 at 03:40 PM.

#22

JK Jedi

Well, I'm getting ready to adjust these arms now. I got the angle finder, but I'm a little unsure how much it's going to help.

Here's the problem.

I pulled one of the arms off, used the jack in the process to make it easier to slide the bolts off. I loosened the nuts on the other arm but didn't remove it, since my original plan was to adjust the length of one arm and then mount it, pull the other arm, adjust length and then install.

So I measure my current pinion angle with the one arm still attached.....it read 8.3 deg. So that doesn't seem like a useful measurement seeing as though, my caster from the alignment shop was 2.9deg driver side, 2.5deg passenger. My drive way, seems pretty "level". I actually put a level on the cement next to each tire, and it showed to be pretty flat at each level.

Next plan. I adjusted the flex joint, so that the joints are parallel. It now measures 22 1/2in on both sides of the control arm. I'm going to adjust it out so it measure 23in.

Hopefully a 1/2in increase in length makes sense and puts me in the 4-5 deg range of caster when all is said and done. I'll measure the pinion angle after install, but I just don't know how much I can trust that angle measurement given all the unknown variables. I really wish I had measured the pinion angle before pulling that arm off.

Summary

Arm length = 22 1/2in => Caster from alignment shop = 2.5 Deg

Arm length = 23in => Caster= hopefully close to 5 deg

I'm going to get an alignment check afterwards regardless. I just didn't want any surprises where I need to adjust them again.

I knew I should have went with Geo brackets!!! LOL!!

Here's the problem.

I pulled one of the arms off, used the jack in the process to make it easier to slide the bolts off. I loosened the nuts on the other arm but didn't remove it, since my original plan was to adjust the length of one arm and then mount it, pull the other arm, adjust length and then install.

So I measure my current pinion angle with the one arm still attached.....it read 8.3 deg. So that doesn't seem like a useful measurement seeing as though, my caster from the alignment shop was 2.9deg driver side, 2.5deg passenger. My drive way, seems pretty "level". I actually put a level on the cement next to each tire, and it showed to be pretty flat at each level.

Next plan. I adjusted the flex joint, so that the joints are parallel. It now measures 22 1/2in on both sides of the control arm. I'm going to adjust it out so it measure 23in.

Hopefully a 1/2in increase in length makes sense and puts me in the 4-5 deg range of caster when all is said and done. I'll measure the pinion angle after install, but I just don't know how much I can trust that angle measurement given all the unknown variables. I really wish I had measured the pinion angle before pulling that arm off.

Summary

Arm length = 22 1/2in => Caster from alignment shop = 2.5 Deg

Arm length = 23in => Caster= hopefully close to 5 deg

I'm going to get an alignment check afterwards regardless. I just didn't want any surprises where I need to adjust them again.

I knew I should have went with Geo brackets!!! LOL!!

#23

Super Moderator

Thread Starter

If you don't mind, humor me and snap a pic once both arms are back on with the angle finder on the very bottom of the pinion flange. If that was reading 8*, the pinion would have been angled pretty far up. I have to think that having one arm off had that twisted a bit? You do have the factory pinion flange right?

EDIT: I take that back, just took a quick peak at it again, it does seem to look like it's pointed up.

Last edited by Rednroll; 08-08-2017 at 05:08 PM.

#24

Super Moderator

Thread Starter

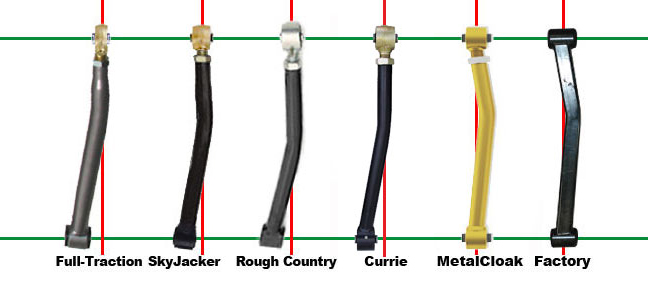

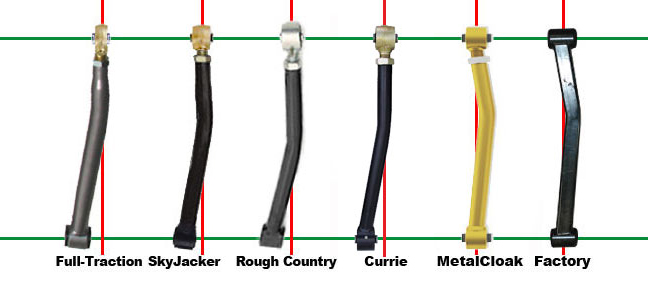

On a side note, I finally understand what Metalcloak was trying to communicate in this image I've seen posted a 100 times before.

I have the RC LCAs installed. I was originally debating between going with Geo brackets or Front LCAs for caster correction, and decided to go with a lower cost adjustable LCA to see if I liked them or not.

I was originally debating between going with Geo brackets or Front LCAs for caster correction, and decided to go with a lower cost adjustable LCA to see if I liked them or not.

Everytime I install something or in this case re-install something, I learn something new. Which is the fun part of all this.

I have the RC LCAs installed.

I was originally debating between going with Geo brackets or Front LCAs for caster correction, and decided to go with a lower cost adjustable LCA to see if I liked them or not.

I was originally debating between going with Geo brackets or Front LCAs for caster correction, and decided to go with a lower cost adjustable LCA to see if I liked them or not.Everytime I install something or in this case re-install something, I learn something new. Which is the fun part of all this.

#25

JK Jedi

I was sold on MC arms long before I was able to buy them. That picture combined with their bushings sold me on em. I've had mine coming up on 2 years and have ZERO regrets. It's hard for me to accept paying full retail for an item, and paying shipping on top of that, but that was one item I was dead set on....and I was tired of waiting for a sale. I have a bunch of different brands on my Jeep. Full set of MC arms was one of my best purchases.

#26

Super Moderator

Thread Starter

I was sold on MC arms long before I was able to buy them. That picture combined with their bushings sold me on em. I've had mine coming up on 2 years and have ZERO regrets. It's hard for me to accept paying full retail for an item, and paying shipping on top of that, but that was one item I was dead set on....and I was tired of waiting for a sale. I have a bunch of different brands on my Jeep. Full set of MC arms was one of my best purchases.

If it does, when/if these RC joints need replacing, instead of rebuilding them I may give that a shot. From the image, the RC bend in the arms look very similar, so my thought was MC maybe addresses that alignment problem with the flex joint assembly by welding on the end of the joint assembly onto the threads with a correction angle.

Here's the video.

Someone in the comments, asked him which joint that was and he replied it was the MC. I can tell by looking at that black joint on the floor, that those are the RC LCAs. I also know it's the RC joint because before I purchased mine RC had a problem with their joints where the threaded lock washers weren't strong enough and the washers were bending out on the trails. RC fixed that with improved/stronger/thicker threaded lock washers. So looking at that joint on the floor, I can see it's been welded to fix that original RC problem. My RC arms came with the stronger threaded lock washers.

https://www.youtube.com/watch?v=5Q1domPqeeE&t=111s

Last edited by Rednroll; 08-08-2017 at 06:24 PM.

#27

8° yea something is wrong, even if the pinion moved removing arms it would drop down. Actually with my DS attached i had to physically pull it down to get a degree more caster.

Sure you are reading the angle correctly? Depending on direction it will read either 88° or 2°

Sure you are reading the angle correctly? Depending on direction it will read either 88° or 2°

#28

Super Moderator

8° yea something is wrong, even if the pinion moved removing arms it would drop down. Actually with my DS attached i had to physically pull it down to get a degree more caster.

Sure you are reading the angle correctly? Depending on direction it will read either 88° or 2°

Sure you are reading the angle correctly? Depending on direction it will read either 88° or 2°

#29

JK Jedi

I don't think the misalignment issue is really all that big a deal. I really like how the MC is aligned similar to the factory, but a lot of people run all kinds of arms that are misaligned like yours. The joint facilitates that. What my concern would be is that the MC joint isn't really made to mount misaligned at all. The guy in the video obviously gets it mounted, but I have to think that it's not quite how MC intended with their own arms. The bend in that RC is pretty different, which by nature would make it seem that replacing the one end of the RC arm with a MC joint would leave things a bit wonky. Unless you're seeing some issue with the arm, I'd just leave it as is. I'd think that if you were wheeling some very aggressive things, you MIGHT see a difference in the arm's joints in general, but I'm not sure that your current arm is really limiting you or anything. I think that before I went and mixed and matched arm pieces, I'd just sell the current ones and buy what you really wanted......but, I do know that you're not fond of throwing money away. I can tell you I've spent a lot of time trying to make certain things work. It's so much easier to just admit an issue and correct it rather than trying to pound a square peg in a round hole.

#30

Super Moderator

Thread Starter

Yeah, I've had no problem with the RC arms other than me originally adjusting their length a little shorter than optimal. They've been installed for over a year now. I was just thinking ahead in the event those RC flex joints wear out. Which is highly likely to happen at some point, since the flex joint is held by a pcv type of plastic.

I have all my mod goals in mind. I try to avoid going down a path which requires me to completely throw away a mod and redo the same mod, just with a different brand name part.

As an example, a big mod goal for me is to eventually do a LS engine swap. I've read where some have regeared to 5.13s, then did a similar HEMI swap and then had to regear back down to 4.10s due to the Hemi swap. That would be a cardinal sin catostrophy for me, in paying for regearing twice. It means I wasn't thinking/planning ahead.

I have all my mod goals in mind. I try to avoid going down a path which requires me to completely throw away a mod and redo the same mod, just with a different brand name part.

As an example, a big mod goal for me is to eventually do a LS engine swap. I've read where some have regeared to 5.13s, then did a similar HEMI swap and then had to regear back down to 4.10s due to the Hemi swap. That would be a cardinal sin catostrophy for me, in paying for regearing twice. It means I wasn't thinking/planning ahead.