Rear OEM Driveshaft yoke hitting tank skid.

#1

JK Freak

Thread Starter

I made 2 days at Rausch Creek and never contacted, but 5 minutes in my back yard and it hit horribly. I thought I blew the rear carrier or broke the gears! I was articulating while crossing a creek out behind the house with the left rear down in an erosion hole, the right rear up on the decline I just came from, the left front up on the next embankment and the right front low in a V-shaped ditch going up that next embankment. The body was still near level as the 2 axles were going totally opposite directions. As the left rear was in that erosion ditch, it sounded horrible and metallic. My heart sank. So I backed up and tried to get more squared up, and that stopped the death sounds.

Once I came back up into the driveway, I climbed under and found this. I am guessing that the fix is a BFH?

Stock control arms

Rear track bar raise braket

Stock rear track bar

3.5" RK springs

It was pretty much in the exact opposite axle configuration as this photo when the driveshaft tried to liberate itself.

Once I came back up into the driveway, I climbed under and found this. I am guessing that the fix is a BFH?

Stock control arms

Rear track bar raise braket

Stock rear track bar

3.5" RK springs

It was pretty much in the exact opposite axle configuration as this photo when the driveshaft tried to liberate itself.

#4

JK Freak

Thread Starter

I'll try to see if the axle is off center. I kind of eyed it up and looked pretty dang close to even between the 2 sides.

#6

JK Freak

Thread Starter

Yes, I have a rear track bar axle side bracket that came with the original Mopar Performance lift. It is a 3" raise bracket.

#7

JK Super Freak

When I had a 4" raised axle bracket my driveshaft barely rubbed the tank. When I raised the axle end higher (5.5") to level the trackbar thinking it would fix the issue I found the driveshaft contacted the tank much worse. I actually had to reshape the tank with a BFH to keep the higher bracket and better roll center.

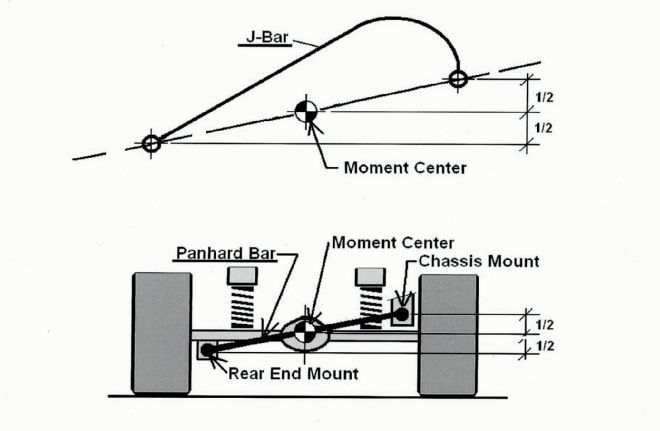

It makes sense when you think about it. The axle pivots during articulation at a point halfway between the trackbar mounts. The higher you raise the mounts the higher the pivot point. Now the driveshaft is below the pivot point and the arc it swings on left to right is larger when you raise the trackbar mounts. (If your trackbar mounts were adjusted to have the pinion line up with the exact halfway point of the trackbar mounts the driveshaft would probably not shift side to side at all during flex. But your roll center would suck, lol.)

OP, your best bet is an adjustable trackbar and push the axle a little farther from the tank, or reshape the tank and its skidplate.

Last edited by Biginboca; 05-23-2016 at 10:50 AM.

Trending Topics

#8

JK Jedi

I find this is not true. The higher you raise the track bar at the axle end the larger the side to side arc the driveshaft swings through as it articulates.

When I had a 4" raised axle bracket my driveshaft barely rubbed the tank. When I raised the axle end higher (5.5") to level the trackbar thinking it would fix the issue I found the driveshaft contacted the tank much worse. I actually had to reshape the tank with a BFH to keep the higher bracket and better roll center.

It makes sense when you think about it. The axle pivots during articulation at a point halfway between the trackbar mounts. The higher you raise the mounts the higher the pivot point. Now the driveshaft is below the pivot point and the arc it swings on left to right is larger when you raise the trackbar mounts. (If your trackbar mounts were adjusted to have the pinion line up with the exact halfway point of the trackbar mounts the driveshaft would probably not shift side to side at all during flex. But your roll center would suck, lol.)

OP, your best bet is an adjustable trackbar and push the axle a little farther from the tank, or reshape the tank and its skidplate.

#9

JK Super Freak

Isnt it below that center on any lifted jeep? The lifting of the jeep is what makes the angle more than factory hence requiring a raised bracket. The way i read what you said it sounds like your saying the driveshaft and axle sway are not related? Regardless you want a centered axle.

I haven't looked at a stock jeep in a while but the stock mount probably places the pinion near that center. (The stock mount is actually below the axle probably for this reason?)

When you lift a jeep you raise the trackbar to correct roll center (handling). This doesn't fix the relationship between axle moment center (midpoint of trackbar mounts) and pinion, they are separated more when you raise the trackbar and the driveshaft swings more sideways under articulation.

Last edited by Biginboca; 05-23-2016 at 11:32 AM.

#10

JK Jedi

Yea it's below that center and the more you raise the trackbar axle end the more below (father from) that center the pinion gets. Thus more sway at the pinion with higher trackbar mounts.

I haven't looked at a stock jeep in a while but the stock mount probably places the pinion near that center. (The stock mount is actually below the axle probably for this reason?)

When you lift a jeep you raise the trackbar to correct roll center (handling). This doesn't fix the relationship between axle moment center (midpoint of trackbar mounts) and pinion, they are separated more when you raise the trackbar and the driveshaft swings more sideways under articulation.