All About Turbochargers

Now that Chrysler has introduced the EcoDiesel, and Banks Engineering is introducing 50-state-legal turbo kits for the YJ Wrangler, let’s take a dive into the wonderful world of turbochargers.

Table of Contents

Part 1: What is a Turbo?

A turbocharger is a form of forced induction that increases the amount of air being forced into the engine during the intake cycle. At least that’s the simple way of looking at it. The reality is turbocharging is very complicated. We’ll get into some finer details like compressor maps (part 7) later into this eight-part series. For now we’re sticking to some of the basic details, so you’ll understand what’s going on inside that magical snail.

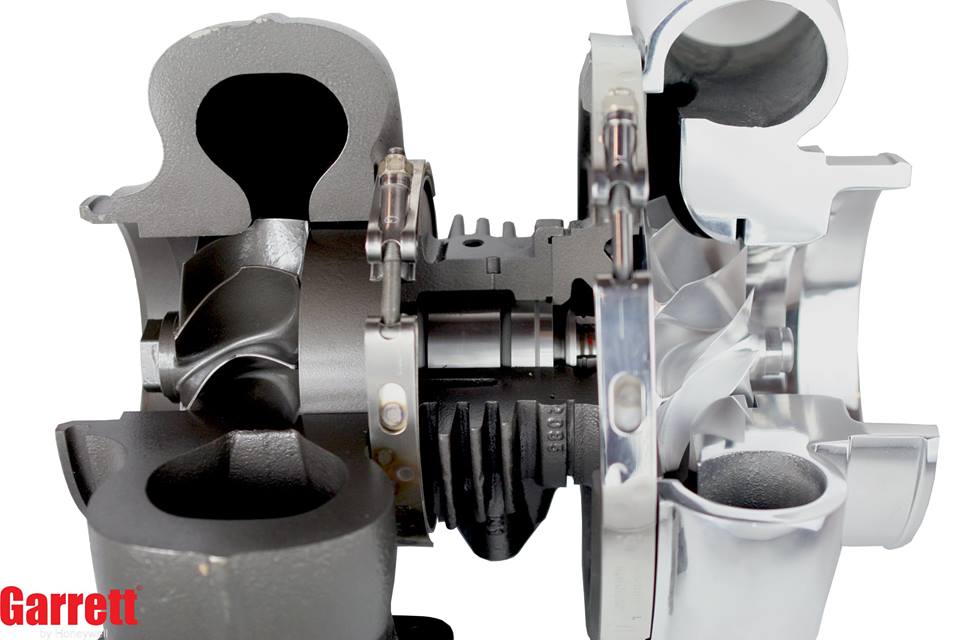

A turbo is made up of a compressor and a turbine. The turbine is on the exhaust side and it drives the compressor wheel that forces air into the intake. The compressor wheel is where the forced air is coming from. It is called a compressor because it increases intake air pressure to a level above atmospheric pressure. This increase in pressure is called “boost”.

Atmosphere is the pressure you feel around you right now, quantified at 14.7 psi at sea level. As you increase or decrease your altitude, you increase and decrease your relative atmosphere. That is the reason why a boost gauge never reads in absolute pressure, and just reads boost pressure.

A turbo may increase the engine’s intake pressure by 7 psi, for example, but when you throw variable atmospheric pressure into the stew of complexity, you begin to see absolute pressure changes that could be explained with math, but I’m not James May, so I won’t bore you with that.

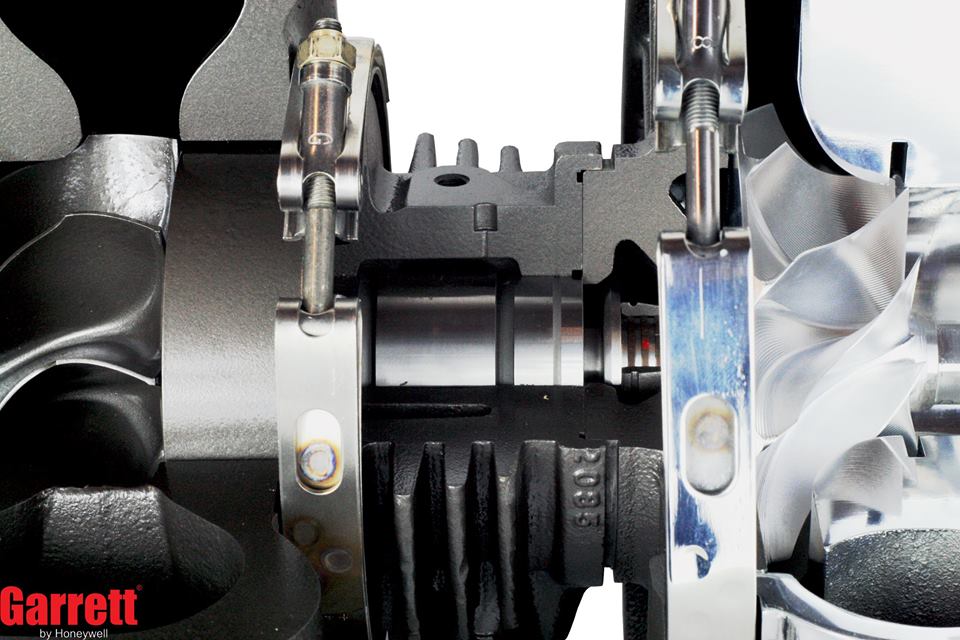

Anyhow, the turbine and compressor wheels are connected by a shaft that will spin on a bearing that will either be a bushing bearing or a ball bearing. Bushing bearings are usually made of a softer metal and rely on oil to keep the shaft spinning freely. A ball bearing will use (as its name implies) ball bearings. The ball bearing style will be more efficient as it does spin more freely, but will also be more expensive.

A final component in some turbos is the wastegate. The wastegate is what monitors the boost pressure and will bleed off exhaust pressure to decrease boost pressure. It will dump the excess exhaust back into the downpipe. In simple turbo systems and most OEM turbos, the wastegate is integrated into the turbo, and you’ll see a little flap on the downpipe side of the turbo near the turbine wheel. There is also an external version you’ll see in the aftermarket and some higher-end turbo cars and turbos that do not have integrated wastegates at all, but I’ll get into those soon. For now, just understand how the wastegate works.

In part 2 we’ll talk about the differences between superchargers and turbochargers, including what excludes a centrifugal supercharger from classification as a turbo.