Wiring method

#1

JK Newbie

Thread Starter

thought i'd throw this out there, this method is waterproof and has long life. also yields clean, professional results. excellent for exterior lighting and general wiring alike- enjoy!

Method.

strip wire end roughly 1/4". slide shrink tube over wire. insert wire into connector, crimp. follow by soldering crimped connection. position shrink tube, apply heat. viola!

Butt connectors, ring terminals and such.

the cheapO colored plastic covered styles from auto stores are worthless.

Except, if you remove inner crimp sleeve from the cheapO's you get something similar to this:

*note* these are solder coated copper terminals, pro style c/o Mad Electrical

Crimpers.

top quality is advisable to obtain solid & secure crimps. jaws should look like this:

Shrink tube.

please stay away from cheapO shrink tubing typically found at auto parts stores. most notably the kind that has a shiny surface, its garbage!

3M has the best product. Its made from Polyolefin, non-flammable, high temp. also provides support at terminal end, reducing flexing and breaking copper wire strands too.

exploded view

assembled view

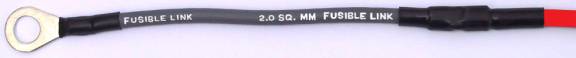

battery terminals

*source- Mad Electrical*

Method.

strip wire end roughly 1/4". slide shrink tube over wire. insert wire into connector, crimp. follow by soldering crimped connection. position shrink tube, apply heat. viola!

Butt connectors, ring terminals and such.

the cheapO colored plastic covered styles from auto stores are worthless.

Except, if you remove inner crimp sleeve from the cheapO's you get something similar to this:

*note* these are solder coated copper terminals, pro style c/o Mad Electrical

Crimpers.

top quality is advisable to obtain solid & secure crimps. jaws should look like this:

Shrink tube.

please stay away from cheapO shrink tubing typically found at auto parts stores. most notably the kind that has a shiny surface, its garbage!

3M has the best product. Its made from Polyolefin, non-flammable, high temp. also provides support at terminal end, reducing flexing and breaking copper wire strands too.

exploded view

assembled view

battery terminals

*source- Mad Electrical*

#3

JK Newbie

Thread Starter

yep

too many times have i seen electrical woes due to shady methods for wire terminating. its especially important to achieve professional results like this when we are constantly abusing our vehicles in puddles, ponds, rivers and even lakes! high vibration, moisture and dirt/dust conditions are devastating on inferior quality installation techniques.

seek out the 3M polyolefin shrink tubing. its disgusting how superior it is to all other tubing on the market.

im sure you can find it elsewhere, but i get it from Mad Electrical (of CA) they sell it in 4 foot lengths ranging from 14gauge- or smaller ($3.19) to 2guage– 1/0 cable ($5.99)

take the additional time to use a method like this and protect your wiring for years

too many times have i seen electrical woes due to shady methods for wire terminating. its especially important to achieve professional results like this when we are constantly abusing our vehicles in puddles, ponds, rivers and even lakes! high vibration, moisture and dirt/dust conditions are devastating on inferior quality installation techniques.

seek out the 3M polyolefin shrink tubing. its disgusting how superior it is to all other tubing on the market.

im sure you can find it elsewhere, but i get it from Mad Electrical (of CA) they sell it in 4 foot lengths ranging from 14gauge- or smaller ($3.19) to 2guage– 1/0 cable ($5.99)

take the additional time to use a method like this and protect your wiring for years

Last edited by Flyin'Squirrel; 08-20-2008 at 12:38 PM.

#4

Good tips... I'm a stickler for quality wiring, and with a little knowledge and extra effort you can produce very professional results.

I'm going to check out the supplier you suggested, but I would also encourage looking at Ancor products for wiring used on the exterior or under the hood. It's marine-grade products are great, though a bit pricey. The shrink wrap has an adhesive liner that melts when the outer wrapper shrinks, making a truly waterproof connection. The wiring uses fine strands of tinned copper, and gauge-for-gauge has a higher amp rating than conventional wire.

I'm going to check out the supplier you suggested, but I would also encourage looking at Ancor products for wiring used on the exterior or under the hood. It's marine-grade products are great, though a bit pricey. The shrink wrap has an adhesive liner that melts when the outer wrapper shrinks, making a truly waterproof connection. The wiring uses fine strands of tinned copper, and gauge-for-gauge has a higher amp rating than conventional wire.

#6

JK Jedi Master

Well, I would be remiss if I didn't point out that by doing that, you've turned your stranded wire, which is designed to flex and not break, into solid core wire, which will break quite easily when flexed. The practice on aircraft (where my experience lies) is to crimp with good crimps and the proper crimping tool.

Having said that, let me say that there will be 222 other responders with varying opinions on this subject. LOL.

Having said that, let me say that there will be 222 other responders with varying opinions on this subject. LOL.

#7

JK Newbie

Thread Starter

that is true, and there is much debate regarding methods.

IMO: two problems need to be addressed in this debate:

1) flexibility (or lack there of), causing wire breakage

2) corrosion

loss of flexibility at a crimp is negated by the fact that a tube of metal is crimped around stranded wire. the metal tube gives the connection rigidity, not the solder. to clarify my statement, the solder is only applied to the crimp site, not traveling down the strands. also, using quality shrink tubing aids prevention of strand breakage by jacketing the bare strands entering the connection.

use of solder essentially "seals" the exposed wire at the crimp, along with shrink tubing, protects the connection from oxidation and corrosion.

to address the 'solid core' wire comparison- solder itself is flexible. when it binds multistrand wire together yes it behaves like a laminate, little to no flex. however it does not snap like solid core. when a section of stranded wire that has been soldered is flexed, the solder flakes and the strands separate.

i can't remember off hand why, but the aviation community abandoned soldered connections for a different reason. temperature cycling comes to mind

IMO: two problems need to be addressed in this debate:

1) flexibility (or lack there of), causing wire breakage

2) corrosion

loss of flexibility at a crimp is negated by the fact that a tube of metal is crimped around stranded wire. the metal tube gives the connection rigidity, not the solder. to clarify my statement, the solder is only applied to the crimp site, not traveling down the strands. also, using quality shrink tubing aids prevention of strand breakage by jacketing the bare strands entering the connection.

use of solder essentially "seals" the exposed wire at the crimp, along with shrink tubing, protects the connection from oxidation and corrosion.

to address the 'solid core' wire comparison- solder itself is flexible. when it binds multistrand wire together yes it behaves like a laminate, little to no flex. however it does not snap like solid core. when a section of stranded wire that has been soldered is flexed, the solder flakes and the strands separate.

i can't remember off hand why, but the aviation community abandoned soldered connections for a different reason. temperature cycling comes to mind