OEM Rubicon Locker Study

#1

JK Jedi Master

Thread Starter

A forum member recently sent me his old Rubicon e-locker.

Here is a quote from the owner:

"...when wheeling in tough areas (sand, mud, rocks &tc.) I put the locker in for a while & then take it out, put the locker in for a while & then take it out, repeat. So, I've used it a lot. My Jeep has 105K miles & I'll bet 15-18K of that is off road."

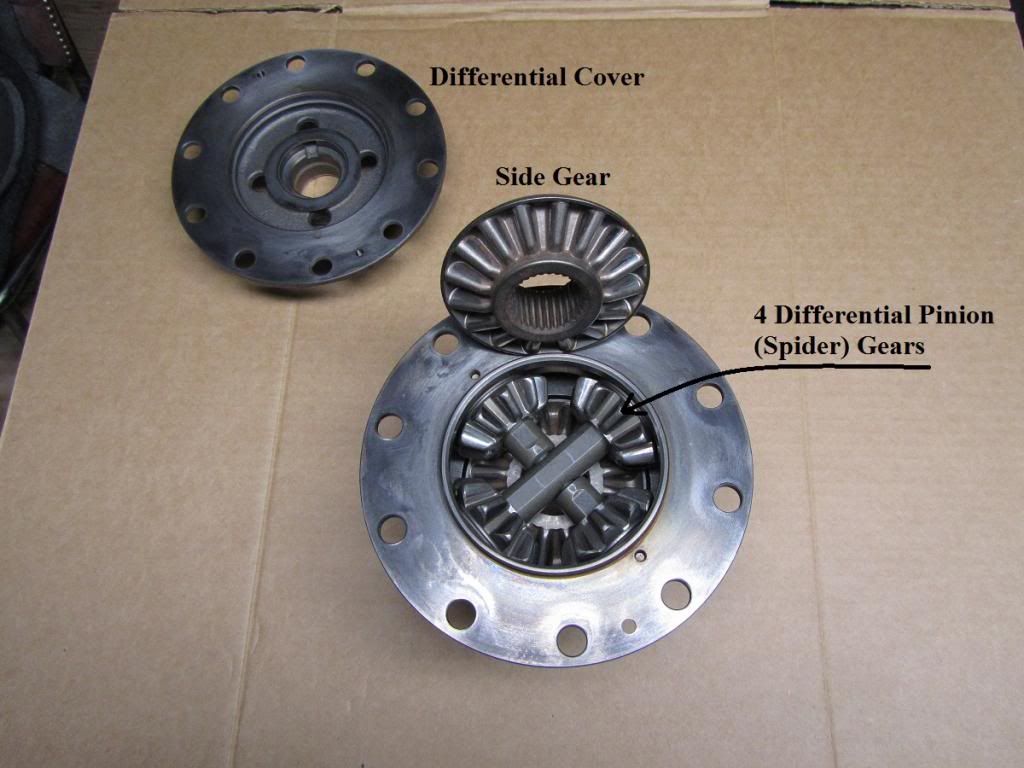

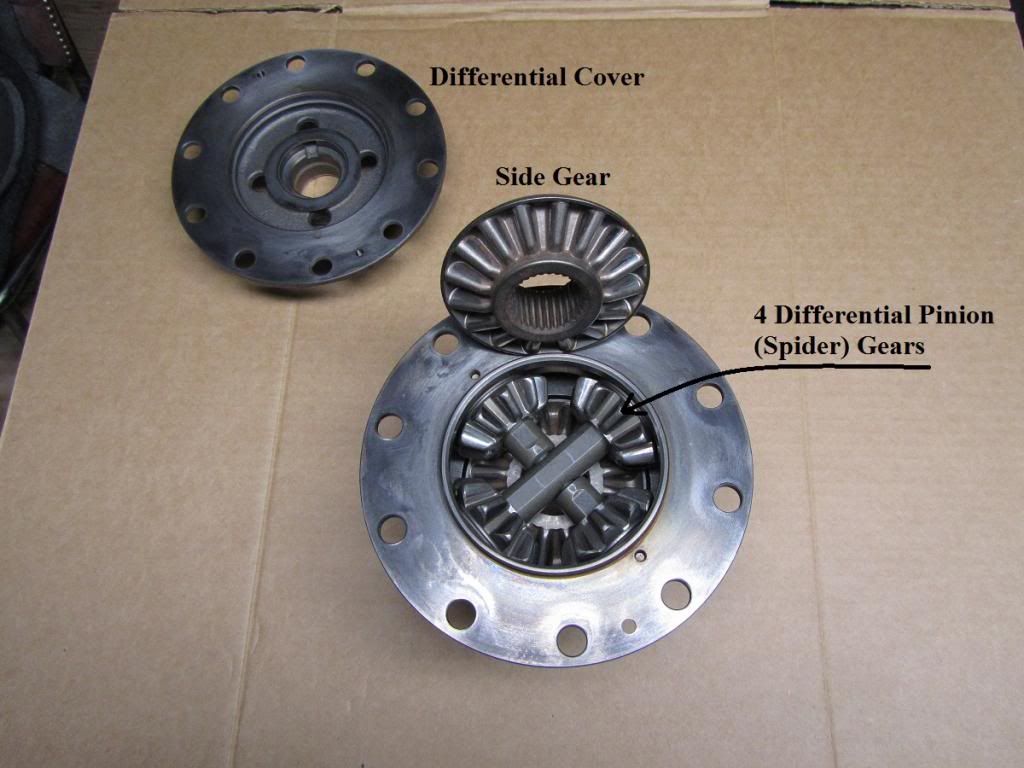

It has seen some good use. The differential and dog clutch show very little wear.

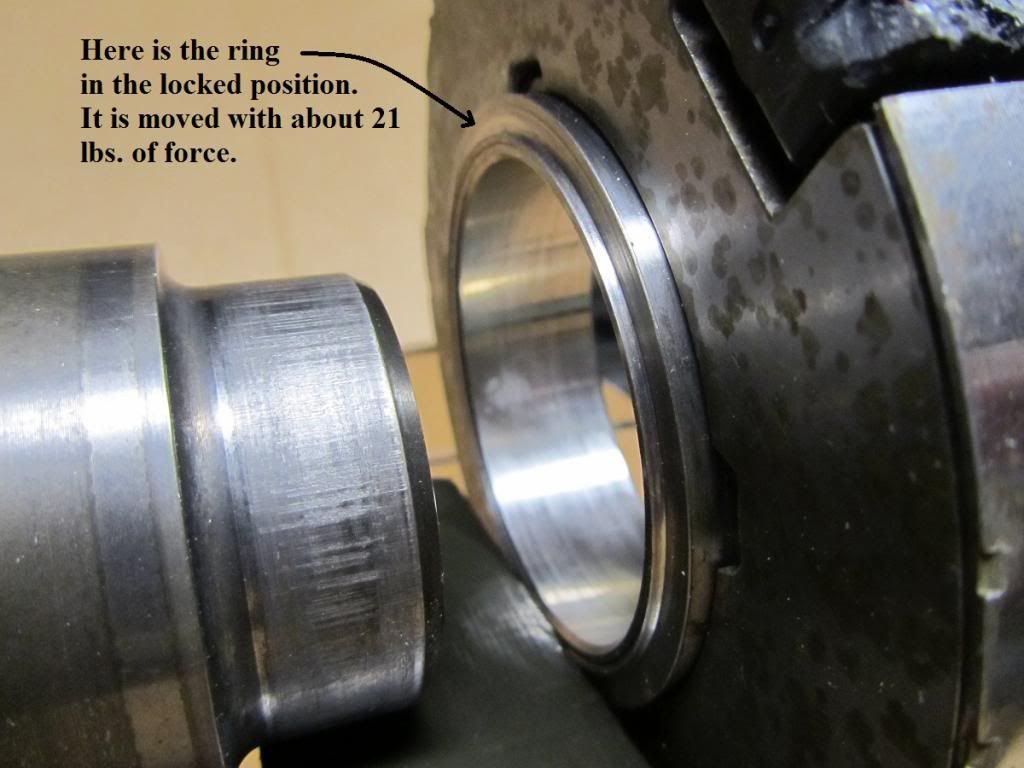

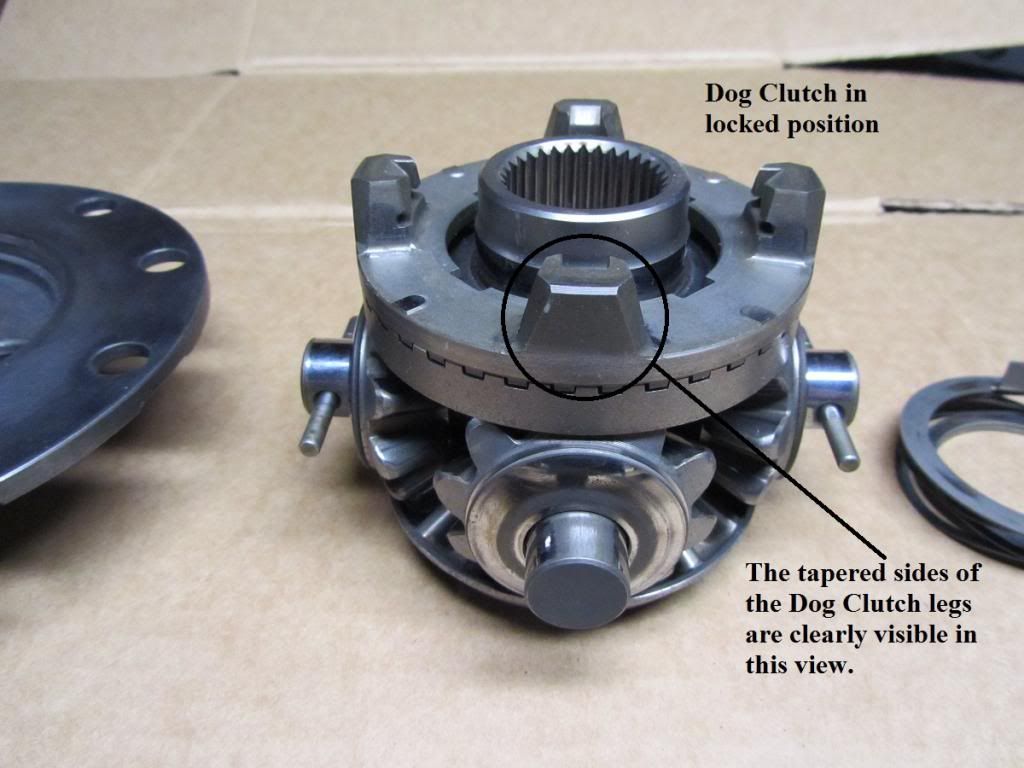

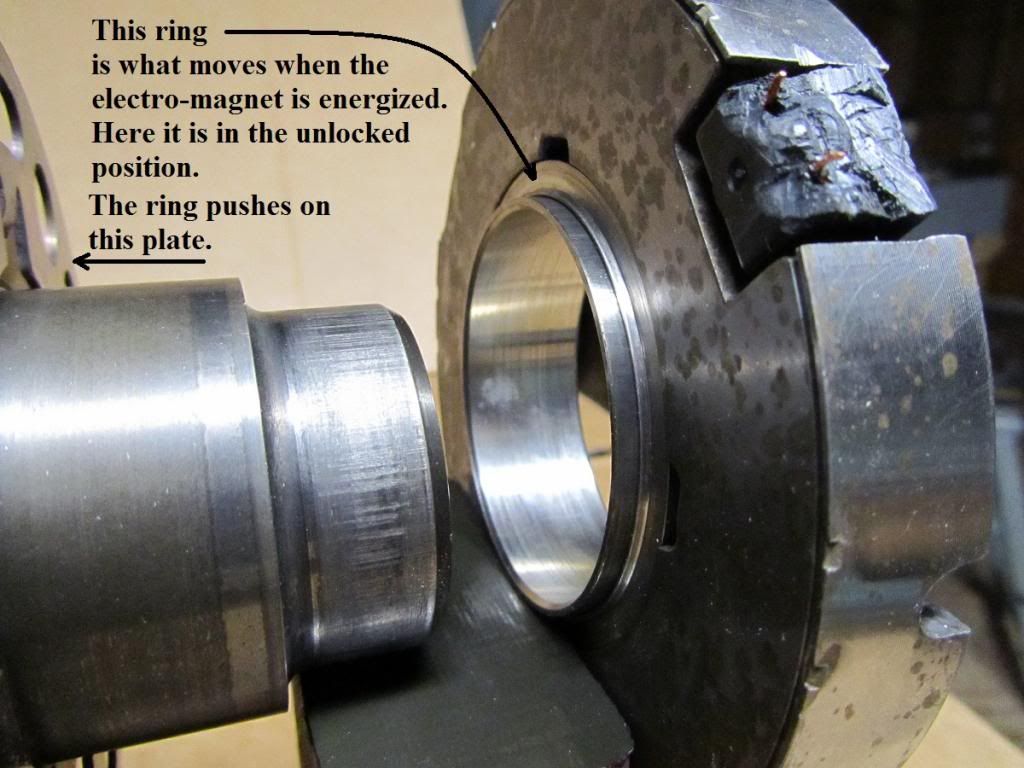

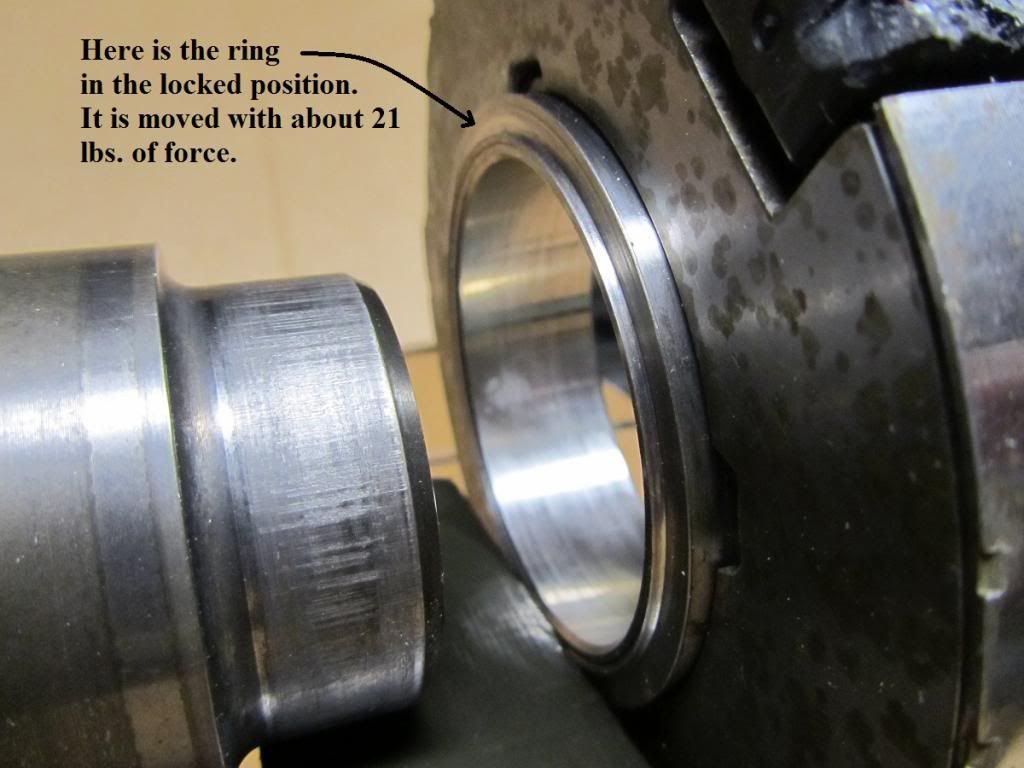

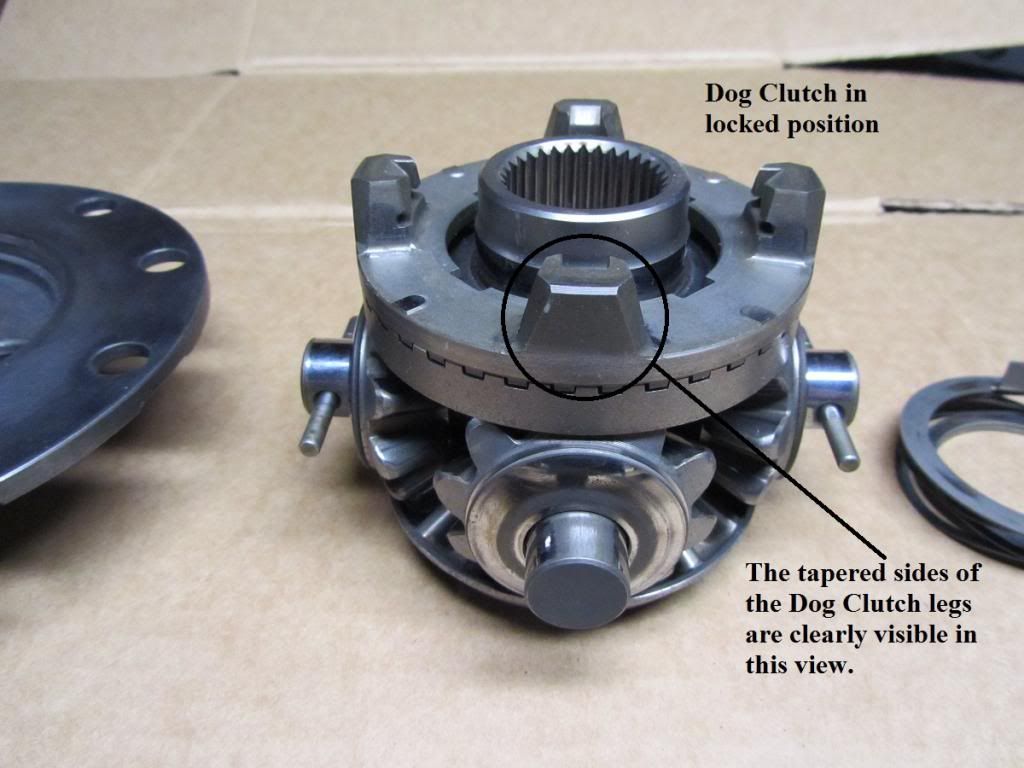

The ring in the 3rd picture below looks quite worn, leaving a small lip at the inner diameter.

That could be the cause of locker ratcheting.

Installing a shim to make up the difference has at least temporarily fixed it in some cases.

Look at this great video to see how a differential works: http://www.youtube.com/watch?v=K4JhruinbWc

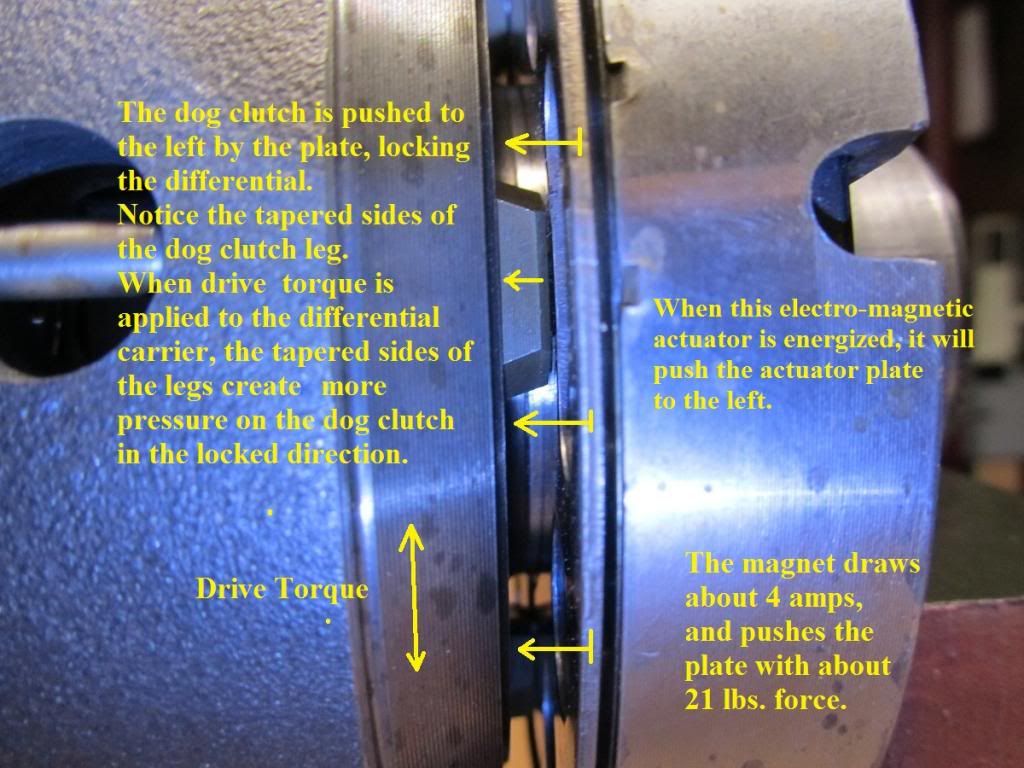

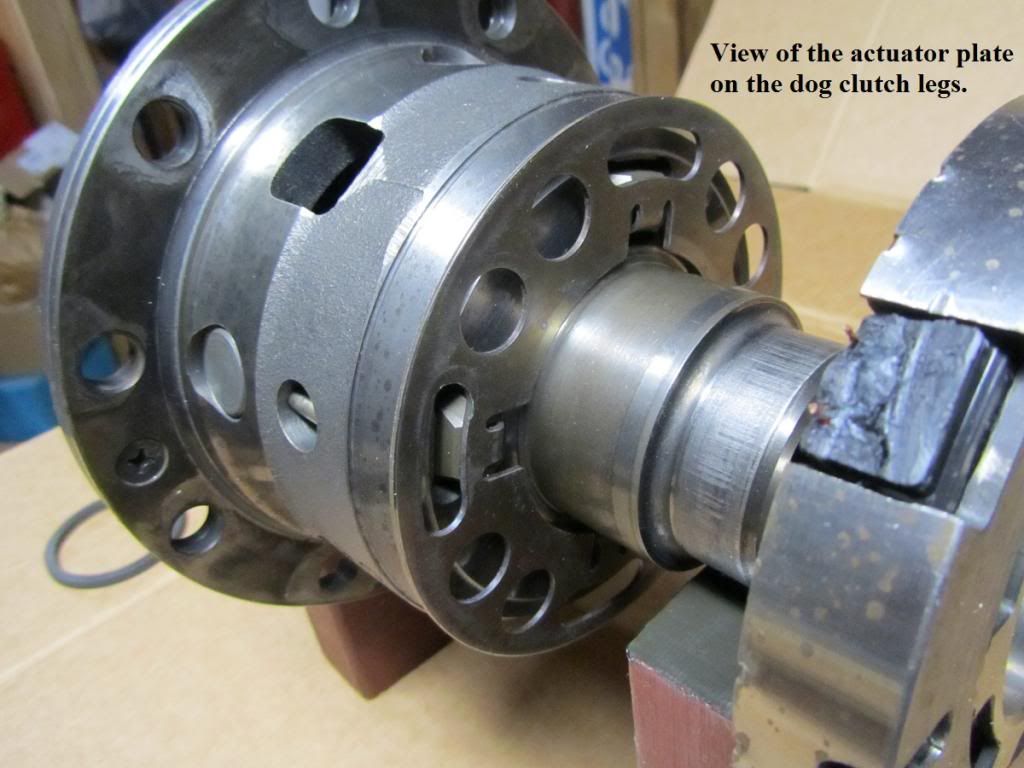

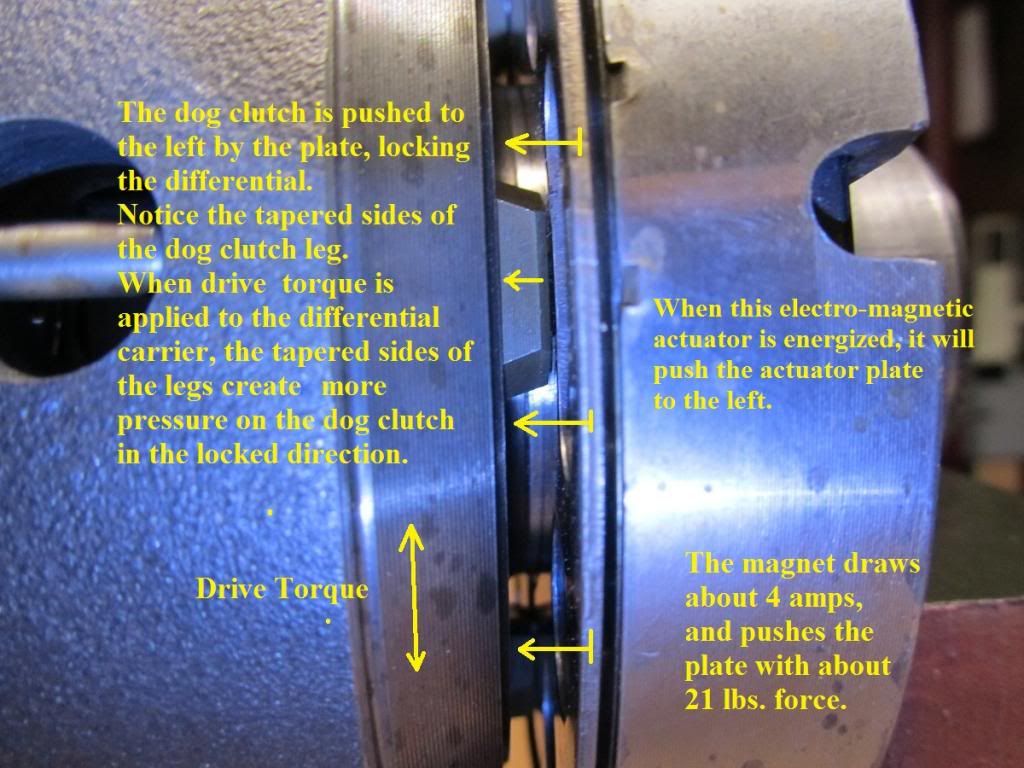

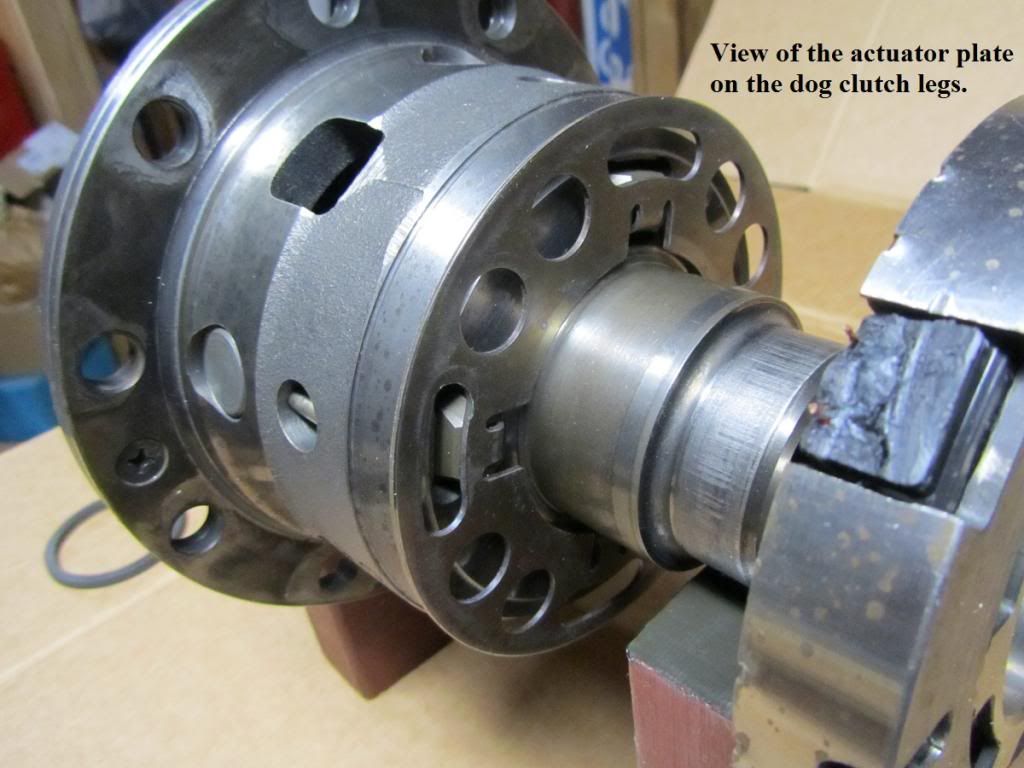

Here is a look at how the Rubicon e-locker works.

Here is a quote from the owner:

"...when wheeling in tough areas (sand, mud, rocks &tc.) I put the locker in for a while & then take it out, put the locker in for a while & then take it out, repeat. So, I've used it a lot. My Jeep has 105K miles & I'll bet 15-18K of that is off road."

It has seen some good use. The differential and dog clutch show very little wear.

The ring in the 3rd picture below looks quite worn, leaving a small lip at the inner diameter.

That could be the cause of locker ratcheting.

Installing a shim to make up the difference has at least temporarily fixed it in some cases.

Look at this great video to see how a differential works: http://www.youtube.com/watch?v=K4JhruinbWc

Here is a look at how the Rubicon e-locker works.

Last edited by ronjenx; 02-11-2013 at 08:52 AM.

#4

JK Jedi Master

Thread Starter

I wouldn't put it back in service because I have no way of knowing the durability of the repair.

I am thinking of a way to make it cable operated from the cab.

#5

JK Enthusiast

I plan to solder some new wires on it, and make an epoxy block over the joint. It will be OK for demonstration purposes.

I wouldn't put it back in service because I have no way of knowing the durability of the repair.

I am thinking of a way to make it cable operated from the cab.

I wouldn't put it back in service because I have no way of knowing the durability of the repair.

I am thinking of a way to make it cable operated from the cab.

#7

JK Jedi Master

Thread Starter

Trending Topics

#8

JK Enthusiast

Join Date: Dec 2008

Location: Albuquerque, NM

Posts: 422

Likes: 0

Received 0 Likes

on

0 Posts

I bought the locker used from someone out of state and due to some very poor packing it arrived in bad shape with mainly a bunch of surface dings and dents. Here's the thread I started. After having the side bearings removed, I was able to take the magnetic actuator off and bench test it. Your thread gave me an idea of what to look for which is the little collar part that pushes out when turned on. The only thing I noticed is that it doesn't slide back in automatically (meaning it stays in locked position) after turning switch off. Any ideas about this? It will slide back in when you give a little help, or turn the gears a little.

#9

JK Jedi Master

Thread Starter

I bought the locker used from someone out of state and due to some very poor packing it arrived in bad shape with mainly a bunch of surface dings and dents. Here's the thread I started. After having the side bearings removed, I was able to take the magnetic actuator off and bench test it. Your thread gave me an idea of what to look for which is the little collar part that pushes out when turned on. The only thing I noticed is that it doesn't slide back in automatically (meaning it stays in locked position) after turning switch off. Any ideas about this? It will slide back in when you give a little help, or turn the gears a little.

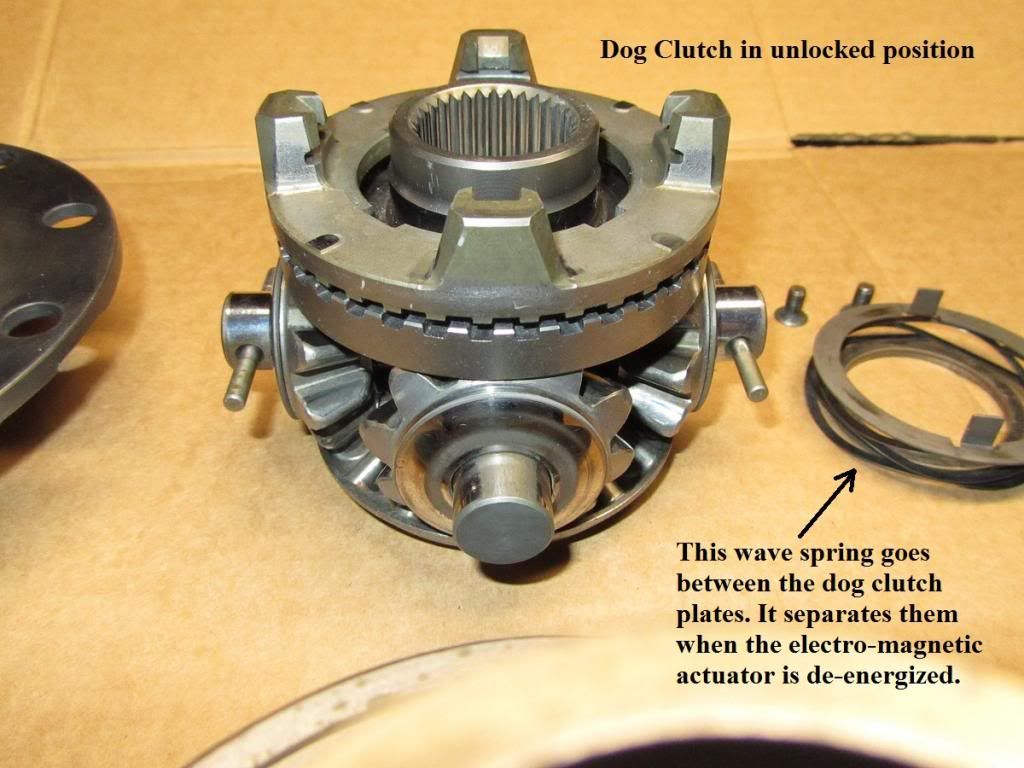

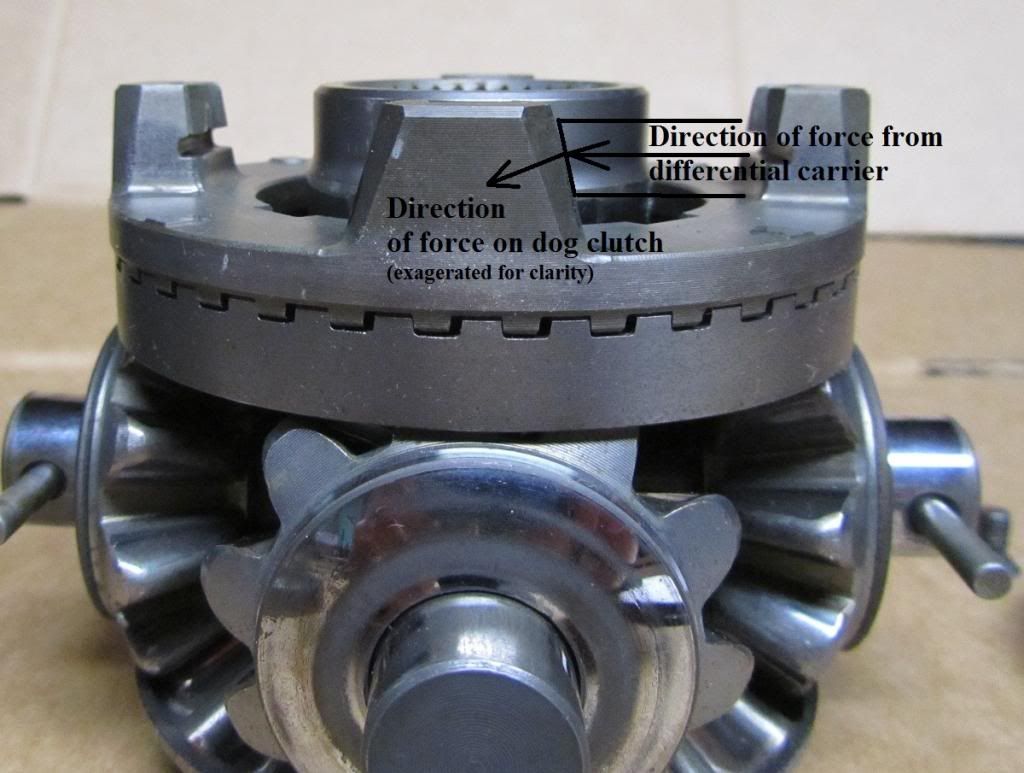

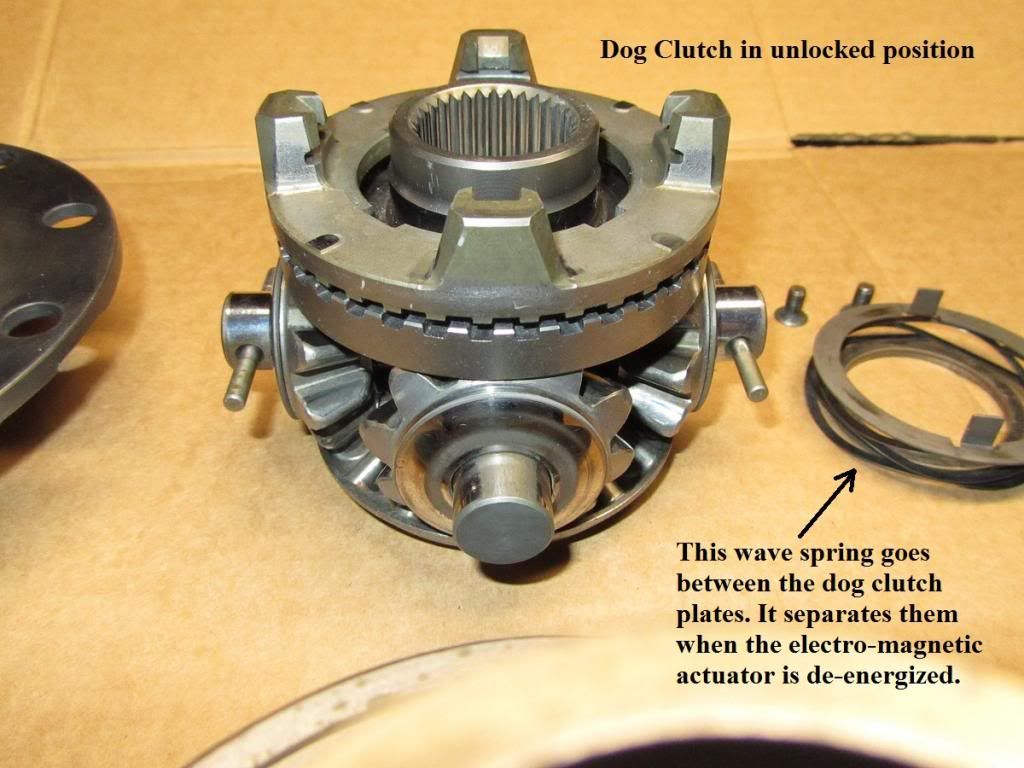

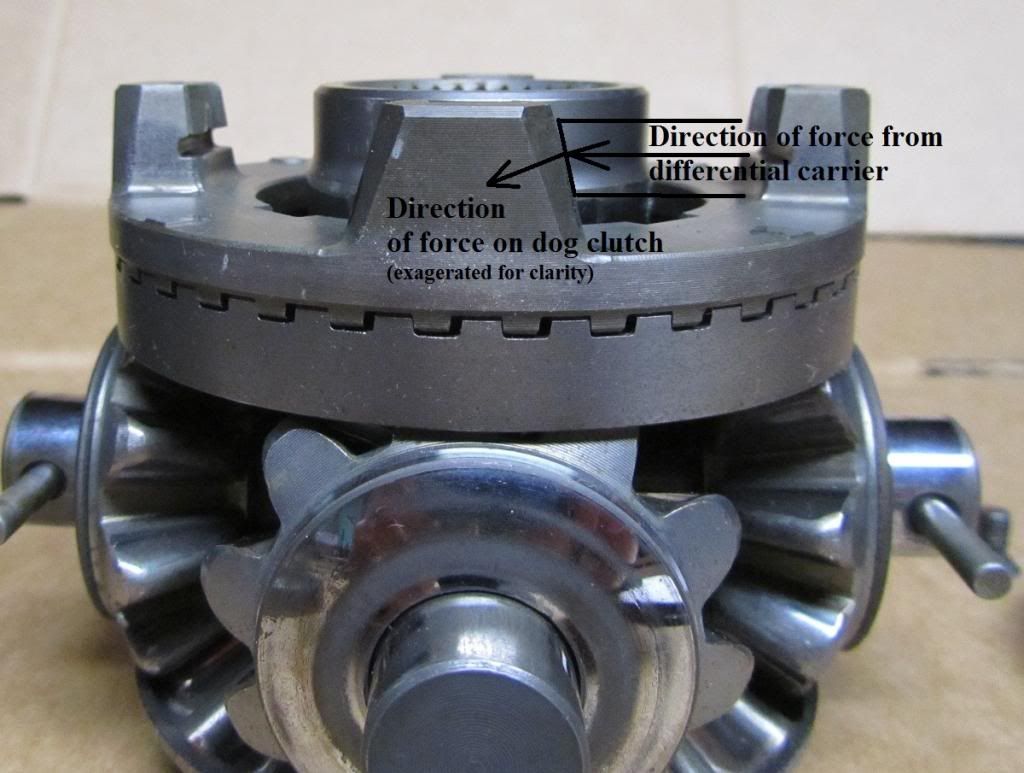

The wave spring pushes the dog clutch apart, which pushes back on the actuator plate, which in turn pushes the ring into the retracted position.

The problem some people have is the ring will sometimes not want to retract. It is a close fit in the magnet housing, and any burr at all will cause interference.

#10

JK Enthusiast

Join Date: Dec 2008

Location: Albuquerque, NM

Posts: 422

Likes: 0

Received 0 Likes

on

0 Posts

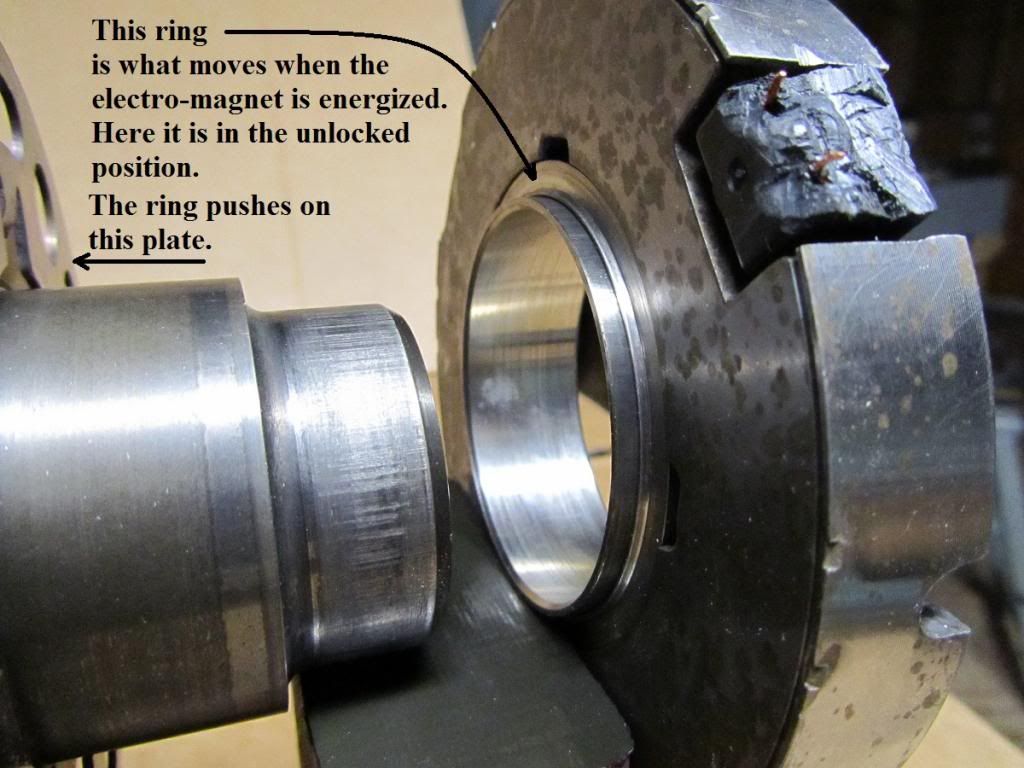

There is nothing in the magnet assembly to cause the ring to retract. The force to retract comes from the wave spring, which is between the dog clutch halves.

The wave spring pushes the dog clutch apart, which pushes back on the actuator plate, which in turn pushes the ring into the retracted position.

The problem some people have is the ring will sometimes not want to retract. It is a close fit in the magnet housing, and any burr at all will cause interference.

The wave spring pushes the dog clutch apart, which pushes back on the actuator plate, which in turn pushes the ring into the retracted position.

The problem some people have is the ring will sometimes not want to retract. It is a close fit in the magnet housing, and any burr at all will cause interference.