Jeep Dealers to Fix Wrangler Bracket Weld Recall In-house

FCA requires them to remove the left wheel, unbolt the track bar, and have an approved ‘Technical Weld Specialist’ repair the bracket.

It isn’t uncommon for new cars to have some growing pains. In some extreme cases, automakers need to issue recalls to correct the issue. Unfortunately, the JL Wrangler has a seriously extreme issue that needs to be addressed. As we reported a few weeks ago, FCA has issued a recall for 18,000 2018-19 Wranglers for a potential track bar bracket weld failure. Now, thanks to Jalopnik, we know how it’s going to address the issue.

A quick overview: From May 7 to August 21, 2018, Jeep’s Toledo plant used an off-seam weld to mount the track bar bracket to the frame. If that weld fails, drivers could lose control of their Jeeps. What’s worse, those welds quickly began failing. This led to an influx of complaints to the National Highway Traffic and Safety Administration.

Luckily, FCA believes the faulty welds are only present on approximately 720 JLs. So if you just bought a brand new Wrangler, you’ll be hearing from FCA shortly. And when you do, here’s what you can expect.

Jeep dealerships will get their hands dirty

You take your Wrangler to your local Jeep dealership and get a free loaner car. Your dealer will then lift it and check the build date on the frame. Numbers greater than or equal to 126 and less than or equal to 156 indicate that it was built during that window. Numbers that aren’t mean your Jeep JL is just fine.

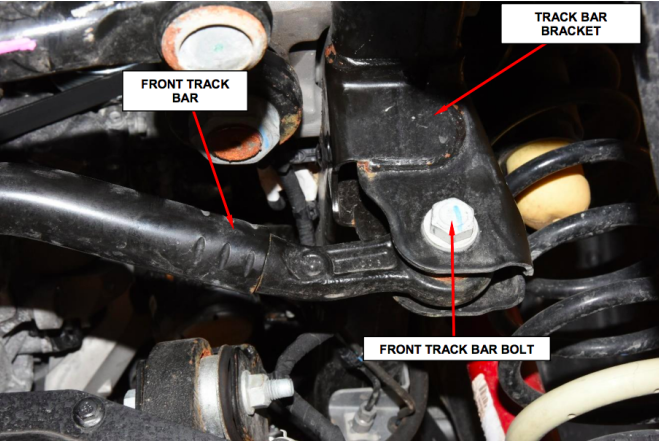

But if your JL falls in that timeframe, dealers will clean and inspect the track bar welds. They’ll mark the three-digit VIN on the outer bracket and photograph both welds. They send those images to a “Track Bar customer care representative” at FCA for inspection. Again, if they look good, then your Wrangler is good to go.

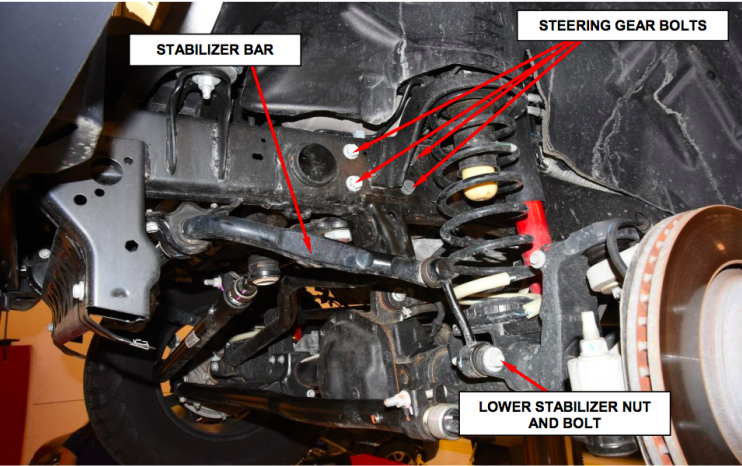

But what if your Jeep is one of the unlucky ones? Well, then people start getting dirty. For the outer weld, dealers will have to remove the left wheel, unbolt the track bar, and have an FCA-approved “Technical Weld Specialist” repair the bracket. For the inboard weld, the left wheel and track bar go, as do the front air dam, steering gear box, and sway bar. With such a new vehicle, none of it should be too difficult. Still, we’re glad it’s a dealer and not us doing this job.

Once the bracket is correctly welded, everything is bolted back up (with new bolts, of course). Your Wrangler gets an alignment, goes for a test drive, and goes home. According to FCA’s billable labor chart (dealers charge FCA for the labor), it should take about 12 minutes for the build date check. For a check and photos, about 18 minutes. Prepping for outboard welds should take about 24 minutes, and prepping for an inboard weld takes nearly two hours. With everything apart, the outboard weld should take an hour. Inboard takes approximately two hours.

This is a pretty messy recall. Nonetheless, we’re glad FCA is tackling it so quickly. Its transparency and thoroughness show that once this fix is out of the way for the 720 or so unlucky Wrangler owners, it should be smooth sailing from here.