Custom modular JK hardtop

#931

JK Super Freak

Thread Starter

This morning I photographed the completed factory hardtop modular conversion. Unfortunately I don't have a 2dr JK to test it on, so we'll have to make do with driveway photos...

Fully assembled. If I didn't tell you it was the finished modular conversion you would probably think it's just any old factory top - the conversion doesn't really affect the outside looks:

Side panels removed. Now you can tell it's the modular conversion :

:

Since I don't have a 2dr JK to show it on, here's a sides-off concept:

A view from the inside - you can see where everything bolts together. The roll bars would block the view of most of the flanges when it's installed.

Disassembled:

All of the step-by-step instructions are written and photographed, as soon as I edit/check them one more time I'll post everything.

Fully assembled. If I didn't tell you it was the finished modular conversion you would probably think it's just any old factory top - the conversion doesn't really affect the outside looks:

Side panels removed. Now you can tell it's the modular conversion

:

:

Since I don't have a 2dr JK to show it on, here's a sides-off concept:

A view from the inside - you can see where everything bolts together. The roll bars would block the view of most of the flanges when it's installed.

Disassembled:

All of the step-by-step instructions are written and photographed, as soon as I edit/check them one more time I'll post everything.

#933

JK Super Freak

Thread Starter

Thank you. Converting a factory top to modular doesn't require intense fab skills, I designed the process and wrote the step-by-step instructions so almost anyone with a little DIY experience could successfully do the conversion. I'll probably get the instructions posted in the next day or two.

#934

JK Super Freak

Thread Starter

And speaking of glass...

This morning I heard from the RV window company that'll be manufacturing the slider windows for the factory hardtop retrofit kit. Today's email included the final pricing for manufacturing the windows, and the price is almost 20% better than I had estimated it would be.

I'm still waiting on manufacturing pricing for the retrofit kit to install the windows in the factory hardtop; the company that will be making them has finished their engineering from my prototype, so I'm just waiting on their pricing people. When that price comes I'll probably have them make a few retrofit kits for testing, and once that's done the company that I did the project for can place the orders for the first production run and decide on the final retail pricing for the kit.

This morning I heard from the RV window company that'll be manufacturing the slider windows for the factory hardtop retrofit kit. Today's email included the final pricing for manufacturing the windows, and the price is almost 20% better than I had estimated it would be.

I'm still waiting on manufacturing pricing for the retrofit kit to install the windows in the factory hardtop; the company that will be making them has finished their engineering from my prototype, so I'm just waiting on their pricing people. When that price comes I'll probably have them make a few retrofit kits for testing, and once that's done the company that I did the project for can place the orders for the first production run and decide on the final retail pricing for the kit.

And now that I've finished the modular work on the 2dr hardtop, I'll be using it for work on the 2dr retrofit kit, the first prototype will be for cargo hatches.

#936

JK Enthusiast

This morning I photographed the completed factory hardtop modular conversion. Unfortunately I don't have a 2dr JK to test it on, so we'll have to make do with driveway photos... Fully assembled. If I didn't tell you it was the finished modular conversion you would probably think it's just any old factory top - the conversion doesn't really affect the outside looks: Side panels removed. Now you can tell it's the modular conversion  : Since I don't have a 2dr JK to show it on, here's a sides-off concept: A view from the inside - you can see where everything bolts together. The roll bars would block the view of most of the flanges when it's installed. Disassembled: All of the step-by-step instructions are written and photographed, as soon as I edit/check them one more time I'll post everything.

: Since I don't have a 2dr JK to show it on, here's a sides-off concept: A view from the inside - you can see where everything bolts together. The roll bars would block the view of most of the flanges when it's installed. Disassembled: All of the step-by-step instructions are written and photographed, as soon as I edit/check them one more time I'll post everything.

: Since I don't have a 2dr JK to show it on, here's a sides-off concept: A view from the inside - you can see where everything bolts together. The roll bars would block the view of most of the flanges when it's installed. Disassembled: All of the step-by-step instructions are written and photographed, as soon as I edit/check them one more time I'll post everything.

: Since I don't have a 2dr JK to show it on, here's a sides-off concept: A view from the inside - you can see where everything bolts together. The roll bars would block the view of most of the flanges when it's installed. Disassembled: All of the step-by-step instructions are written and photographed, as soon as I edit/check them one more time I'll post everything.

#937

JK Super Freak

Thread Starter

I posted the step-by-step instructions for the factory modular hardtop conversion here: http://www.expeditionportal.com/foru...top-to-modular

#938

JK Freak

Join Date: Nov 2010

Location: Scottsdale, AZ

Posts: 698

Likes: 0

Received 0 Likes

on

0 Posts

I posted the step-by-step instructions for the factory modular hardtop conversion here: http://www.expeditionportal.com/foru...top-to-modular

#939

I posted the step-by-step instructions for the factory modular hardtop conversion here: http://www.expeditionportal.com/foru...top-to-modular

#940

JK Super Freak

Thread Starter

Since the hardtop shell I converted to modular doesn't have side windows, I've been thinking about doing another experiment - snap-in soft side windows. They could either be completely removed, or rolled up to provide lots of air to the back. I haven't finalized all the design details yet, but I'm thinking about doing that and sewing a pair for the modular hardtop. Something like this:

I've also got a preliminary design for snap-in hard windows, those and the soft windows above could cover all 4 seasons.

Here's what I'm thinking for weatherstripping the soft window and the hard window.

In this photo I've set some snap studs in place to check the clearances:

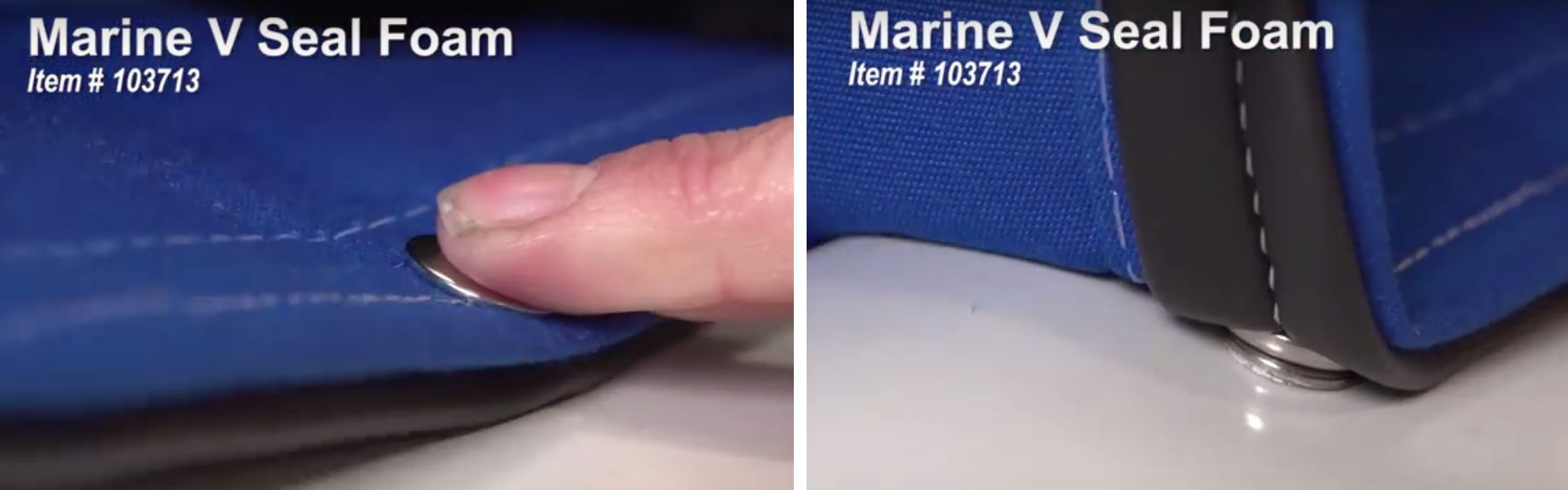

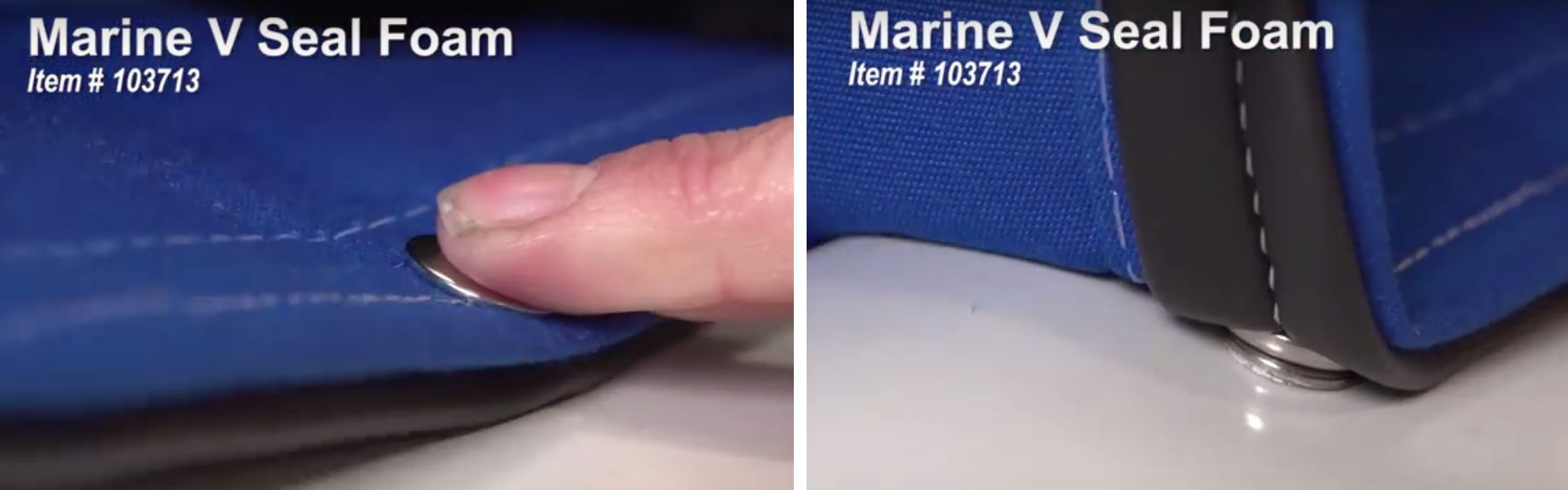

The soft window would be weatherstripped with Marine V-Seal foam from SailRite. It's designed to seal around snaps:

The hard window would be weatherstripped with a push-on trim seal like this sample on a small scrap of Lexan:

The trim seal for the hard window won't conflict with the snap-studs for the soft window, there's plenty of clearance between the stud and where the hard window weatherstrip needs to seal, which allows both soft and hard windows to be interchangeable. The hard window wouldn't use the snaps, it would be secured with latches from the inside.

The hard window would be Lexan, for two reasons - first, doing custom windows with compound curves would be cost-prohibitive, and second, Lexan windows wouldn't need any special care when they're removed, except perhaps putting them in a storage bag to prevent scratches, but you would be able to just throw them in the back of the Jeep in the bag without worrying about breakage like you would with glass windows.

It would also be possible to use the same push-on weatherstrip with the factory glass, but the problem would be finding a strong enough way to bond the latches to the glass.

A screened soft window to keep dogs in could be done the same as a clear vinyl soft window, just with fiberglass screen in place of the vinyl.

I've also got a preliminary design for snap-in hard windows, those and the soft windows above could cover all 4 seasons.

Here's what I'm thinking for weatherstripping the soft window and the hard window.

In this photo I've set some snap studs in place to check the clearances:

The soft window would be weatherstripped with Marine V-Seal foam from SailRite. It's designed to seal around snaps:

The hard window would be weatherstripped with a push-on trim seal like this sample on a small scrap of Lexan:

The trim seal for the hard window won't conflict with the snap-studs for the soft window, there's plenty of clearance between the stud and where the hard window weatherstrip needs to seal, which allows both soft and hard windows to be interchangeable. The hard window wouldn't use the snaps, it would be secured with latches from the inside.

The hard window would be Lexan, for two reasons - first, doing custom windows with compound curves would be cost-prohibitive, and second, Lexan windows wouldn't need any special care when they're removed, except perhaps putting them in a storage bag to prevent scratches, but you would be able to just throw them in the back of the Jeep in the bag without worrying about breakage like you would with glass windows.

It would also be possible to use the same push-on weatherstrip with the factory glass, but the problem would be finding a strong enough way to bond the latches to the glass.

A screened soft window to keep dogs in could be done the same as a clear vinyl soft window, just with fiberglass screen in place of the vinyl.